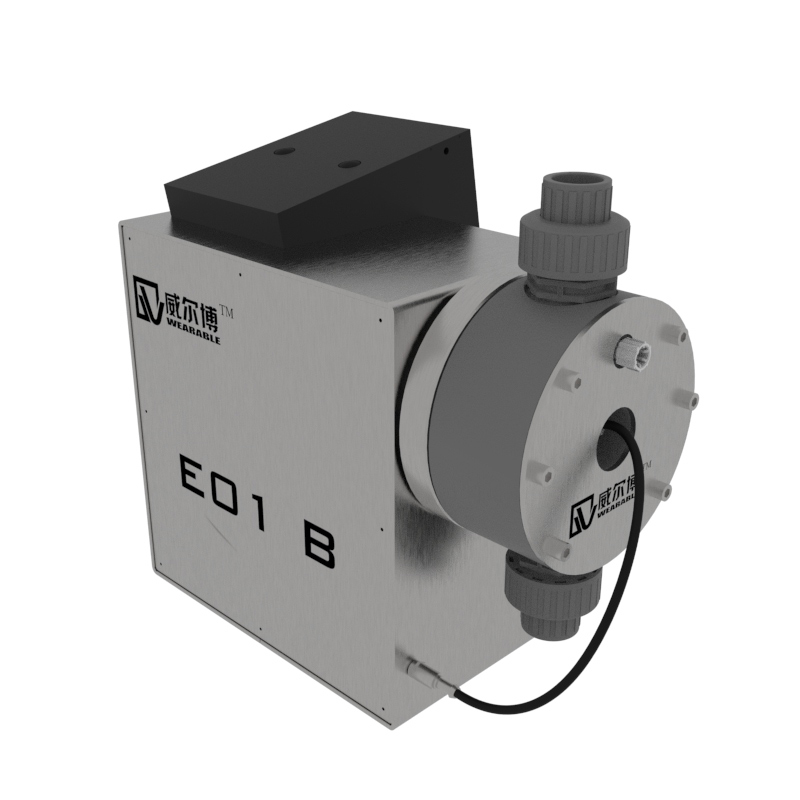

E01B 200-04

| TECHNICAL PROJECT | UNIT | E01B 200-04 |

| Turn-down ratio(Setting Range) | 1:X | 1:3916 |

| Maximum flow rate in standard mode | L/h | 200 |

| Maximum viscosity in 50% slow mode | L/h | 100 |

| Maximum viscosity in 25% slow mode | L/h | 50 |

| Minimum flow rate | L/h | 0.06 |

| Maximum operating pressure (Back Pressure) | Bar | 4 |

| Accuracy of repeatability | %FS | ±0.5~1 |

Our Chemical-Resistant Digital Dosing Pump is a diaphragm metering pump driven by advanced algorithms (Huawei chip) and servo motors, delivering exceptional dosing accuracy with a deviation of just 0.24%. Designed for intelligent, full-automatic operation, it provides consistent and precise chemical delivery across a wide range of industrial applications.

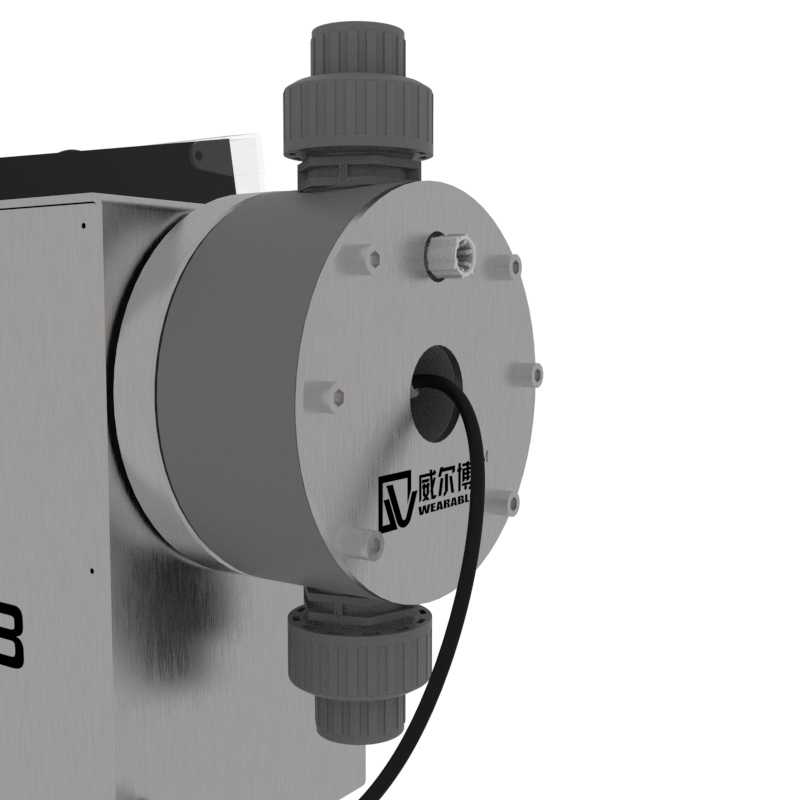

In addition, our digital metering pumps are equipped with YLC sensors, it is a pressure sensor, continuously monitor pipeline pressure, diaphragm status, bubble,pipeline blockage to promise high precision.If any abnormal condition appear,YLC sensor can send alarm display on the screen.(If the air come into the pipeline,we can set automatic exhaustion)

Key Features

The Digital Dosing Pump is designed to simplify chemical dosing without compromising on accuracy. With a user-centered design and intelligent control system, this pump combines ease of use with highly precise measurement, making it ideal for applications that demand both reliability and convenience.

At the core of the system is its Easy Operation. The pump features an intuitive interface with clear digital displays, streamlined navigation, and minimal setup requirements. Even first-time users can quickly configure dosing rates, select from various operation modes, and begin dosing with confidence. Maintenance is equally straightforward, thanks to user-friendly diagnostics and tool-free access to key components.

Complementing its simplicity is the pump’s standout feature: Precise Measurement. It delivers consistent, accurate dosing even in dynamic pressure and flow conditions. Whether handling corrosive chemicals, viscous fluids, or low-volume additives, the system ensures each dose is delivered exactly as intended. Built-in sensors and advanced control algorithms automatically adjust dosing in real time to match flow variations, reducing waste and ensuring consistent process quality.

With additional features such as quick installation, multiple external control options, and advanced anomaly detection, the Digital Dosing Pump is not just accurate—it’s effortless. Whether you’re scaling up operations or looking to upgrade from manual dosing, this solution offers precision without the complexity.

Function

Manual mode:It is the basic function ,You can set any flow rate you want through the control button,milliliter per minute. (press the button to start set and press it to finish)

Concentration mode:you can automatically proportion the concentration of dosing chemcial though this mode. It has three choices,the difference is precision higher(PPM million grade)Now we can enter into first one,you can set the original concentration of your liquid and the dilute concentration you want.

Impulse mode:In this mode,we can connect outside impulse signal though the interface input3,adjust the flow rate according to the impulse signal;if we set 1 milliliter/impulse signal,and we set 1 hz,the flow rate is 60 milliliter per minute.

Impulse control:It is always used for impulse water meter,our pump can automatically adjust the flow rate according to the flow rate change of impulse water meter.

Batch mode:you can set how much liquids you need to convey at one time

Current mode:0-20MA(milliampere)4-20MA

Pause-work:For example,you can set the working hours to 240minutes,and interval for 30 minutes,it means the pump will work for 4 hours and stop work for 30 minutes,when interval time over it will restart work (Cycle and continuous operation)according to the working time and intervals you set.

Weekly mode:You can set the start working time,continue working time(duration)and also the flow rate.You can set the maximum 20 in a week,from Monday to Sunday.

ROC mode:connect external control and start or stop the pump though the external button,digital control box

Marginal Notes

[1] Test results based on an altitude below 100 meters, using pure water as the medium at a temperature of 20°C

[2] Pressure differential can be increased by adding a back pressure valve to the outlet

[3]Optional flow components with different materials are available to extend the temperature range og the medium.For more details,please consult the manufacturer.