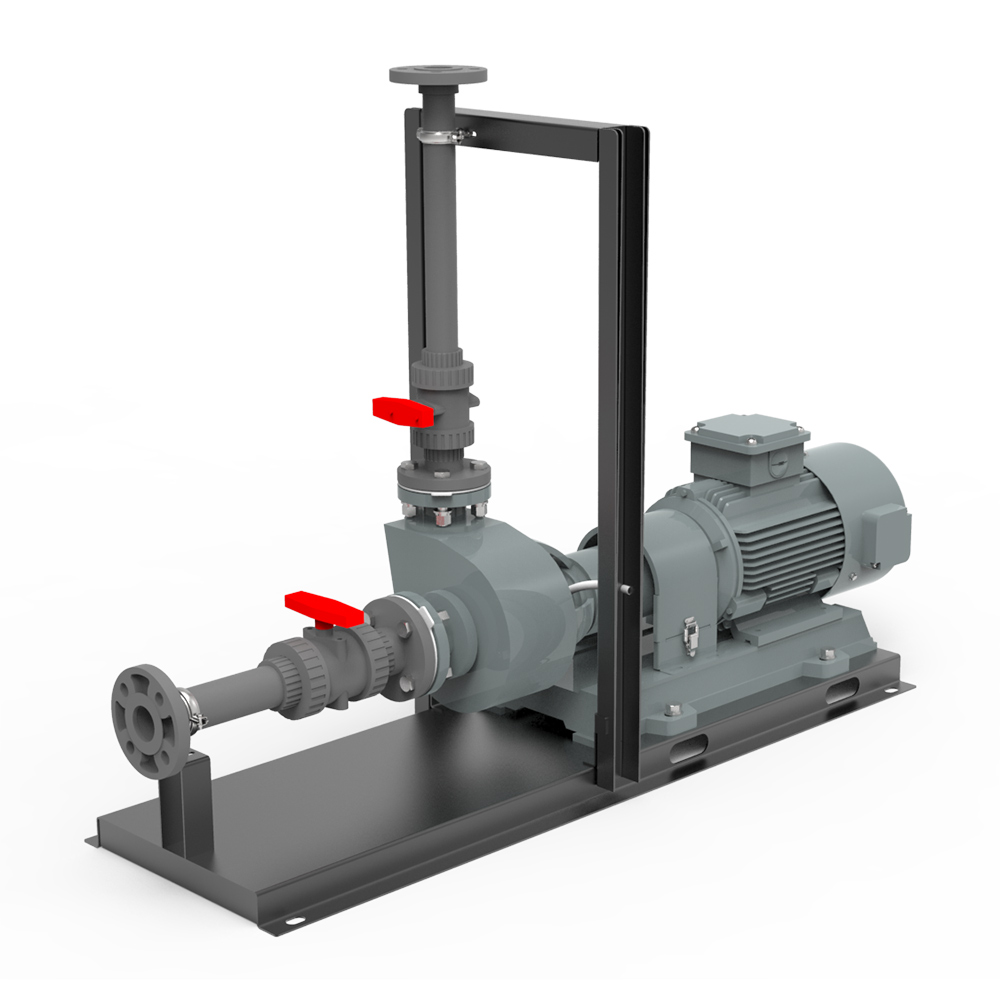

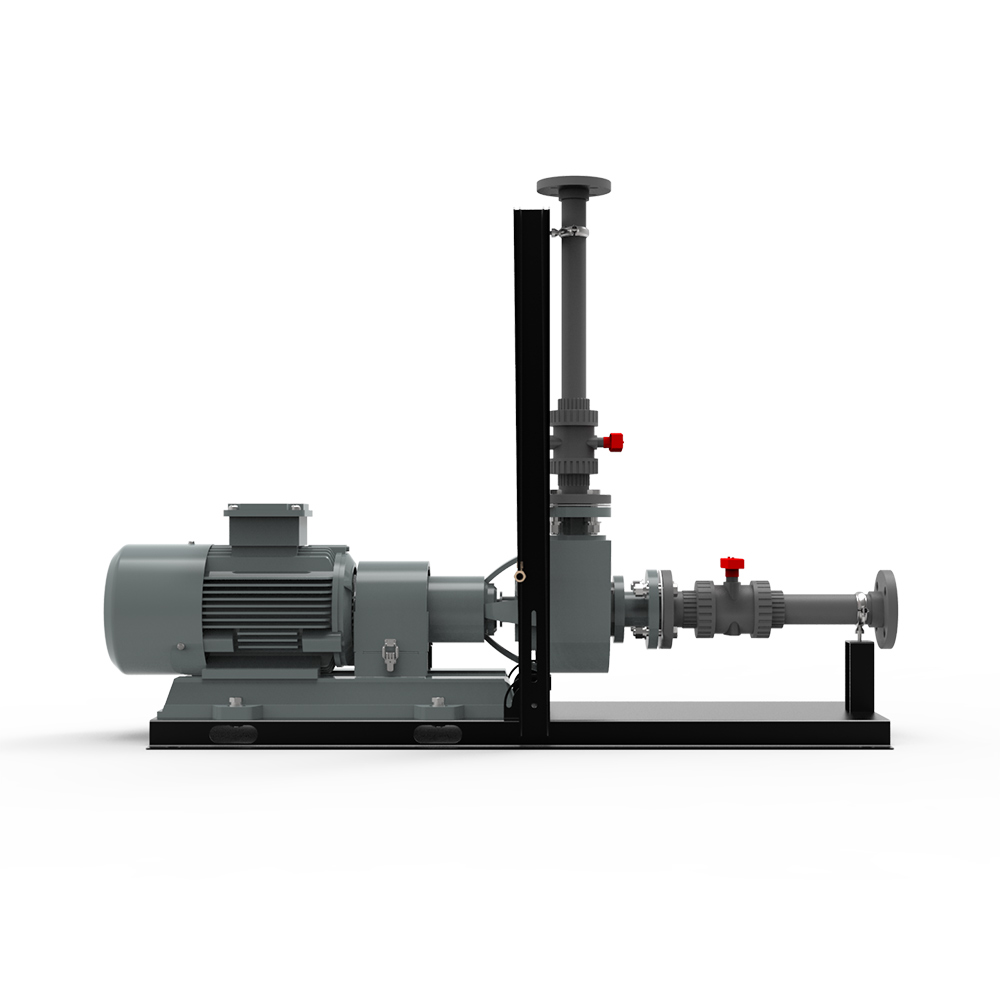

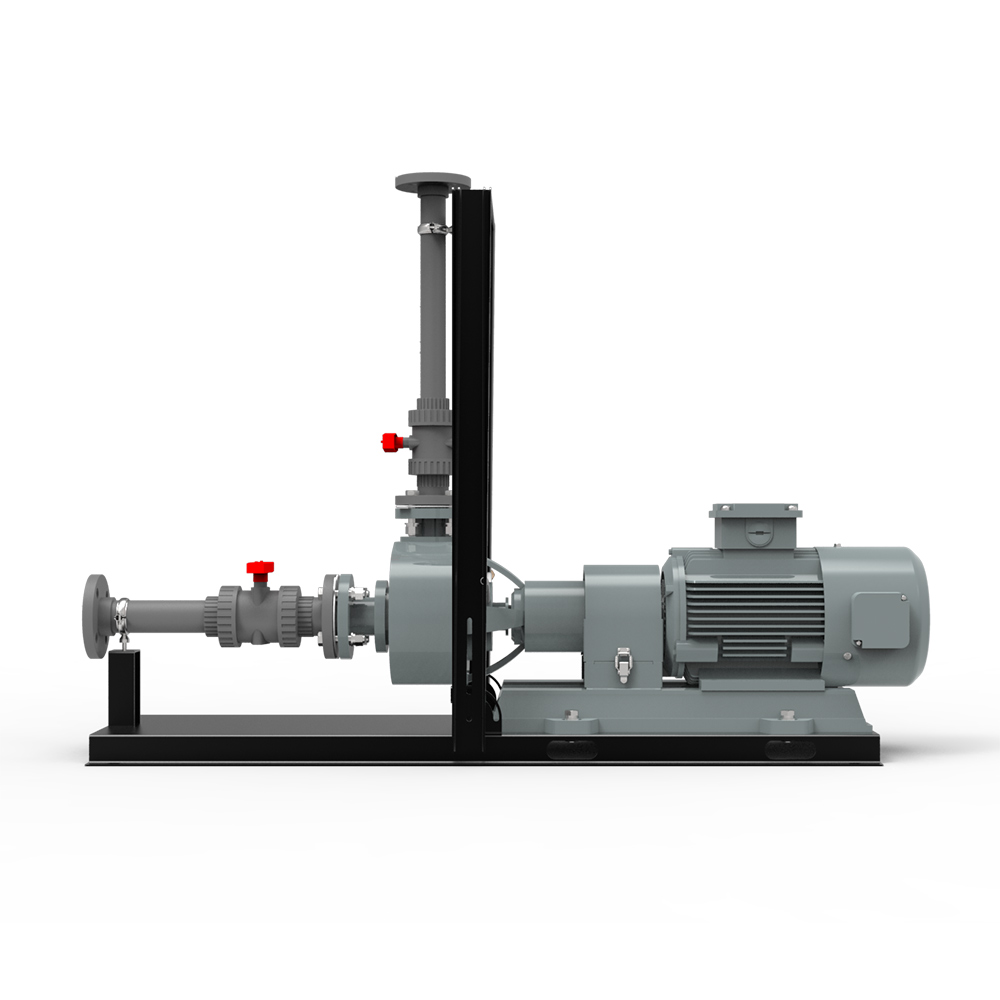

50FUH-30-15-30C3N

Chemical pumps are used to transfer, dose, and circulate corrosive or hazardous liquids in industrial processes. They are engineered to handle acids, alkalis, solvents, and disinfectants, making them essential in industries such as water treatment, chemical processing, pharmaceuticals, and textiles. Designed with corrosion-resistant materials, sealed structures, and drive options like magnetic coupling or diaphragm mechanisms, chemical pumps ensure safe and reliable operation. Their adaptability supports applications including chemical injection, pH control, fluid neutralization, and reagent mixing, delivering stable performance, system protection, and low maintenance under demanding operating conditions.

The Chemical Pump is a specialized fluid handling solution designed for the safe, efficient, and reliable transfer of aggressive, high-purity, or temperature-sensitive liquids. Whether dealing with highly acidic solutions, caustic alkalis, or volatile organic compounds, this pump is engineered to provide long-lasting performance under challenging industrial conditions.

Corrosion-resistant chemical pumps are typically constructed from corrosion-resistant materials such as fluoroplastics, stainless steel, and high-grade composites to withstand the chemical nature of the fluids being conveyed. These pumps are capable of handling a wide range of liquid types—neutral or corrosive, clean or containing particulates, cold or hot—making them highly versatile.

They are often designed as centrifugal, magnetic drive, or diaphragm pumps depending on the required flow rate, pressure, and chemical compatibility. With options for both horizontal and vertical configurations, chemical pumps can be seamlessly integrated into complex industrial systems.

Product Advantages

1. Broad Chemical Compatibility

These pumps are capable of handling a wide spectrum of media, including:

- Inorganic acids like sulfuric acid, nitric acid, hydrochloric acid, and phosphoric acid

- Alkaline solutions such as sodium hydroxide and sodium carbonate

- Oxidizers including hydrogen peroxide

- Salt solutions and petrochemicals

- Organic compounds and other corrosive raw materials

Thanks to high-grade wetted materials, the pumps maintain structural integrity even at elevated temperatures and concentrations.

2. Safe and Leak-Free Operation

Many chemical pump designs, particularly magnetic drive pumps and diaphragm pumps, eliminate dynamic seals and reduce the risk of leakage. This ensures a safer working environment, especially when dealing with hazardous or toxic substances.

3. Durability and Low Maintenance

With no metal contact between moving parts and media in some designs, wear and corrosion are minimized. Maintenance intervals are extended, and replacement parts such as seals or diaphragms are often easy to access and replace.

4. High Efficiency and Consistent Flow

Chemical pumps provide stable flow rates and pressure control, essential for process reliability in production lines and laboratories. Variable frequency drive (VFD) options or automatic control modes can be integrated for dynamic flow adjustment.

5. Versatile Installation Options

These pumps are compact and available in various mounting styles, allowing flexibility in system design and layout. They can be installed in both fixed and mobile setups, indoors or in harsh outdoor environments.

Applications

Due to their excellent chemical resistance and flexible performance, chemical pumps are widely used across multiple sectors:

- Sewage Treatment: For dosing neutralizing agents, acids, alkalis, and coagulants

- New Energy: Handling electrolytes and battery-grade chemicals in lithium-ion battery production

- Metallurgy and Chemicals: For transporting reactive solutions used in refining and synthesis

- Artificial Culture (Aquaculture): For managing water quality with precision chemical dosing

- Printing and Dyeing: Used to transfer dyes, bleaches, and other color-processing chemicals

- Metal and Non-Metal Beneficiation: In ore treatment plants where chemical separation is required

- Laboratories: For precision delivery of corrosive or temperature-sensitive substances

- Pulp and Paper: Handling bleaching agents and pH control solutions in processing lines

Chemical pumps play a critical role in modern industry by offering safe, efficient, and durable transport of specialized and corrosive fluids. From large-scale manufacturing to laboratory-scale precision tasks, these pumps are built to meet the exacting standards of performance and safety. With their broad media compatibility and robust design, chemical pumps are a foundational component of any operation that handles aggressive or reactive liquids.