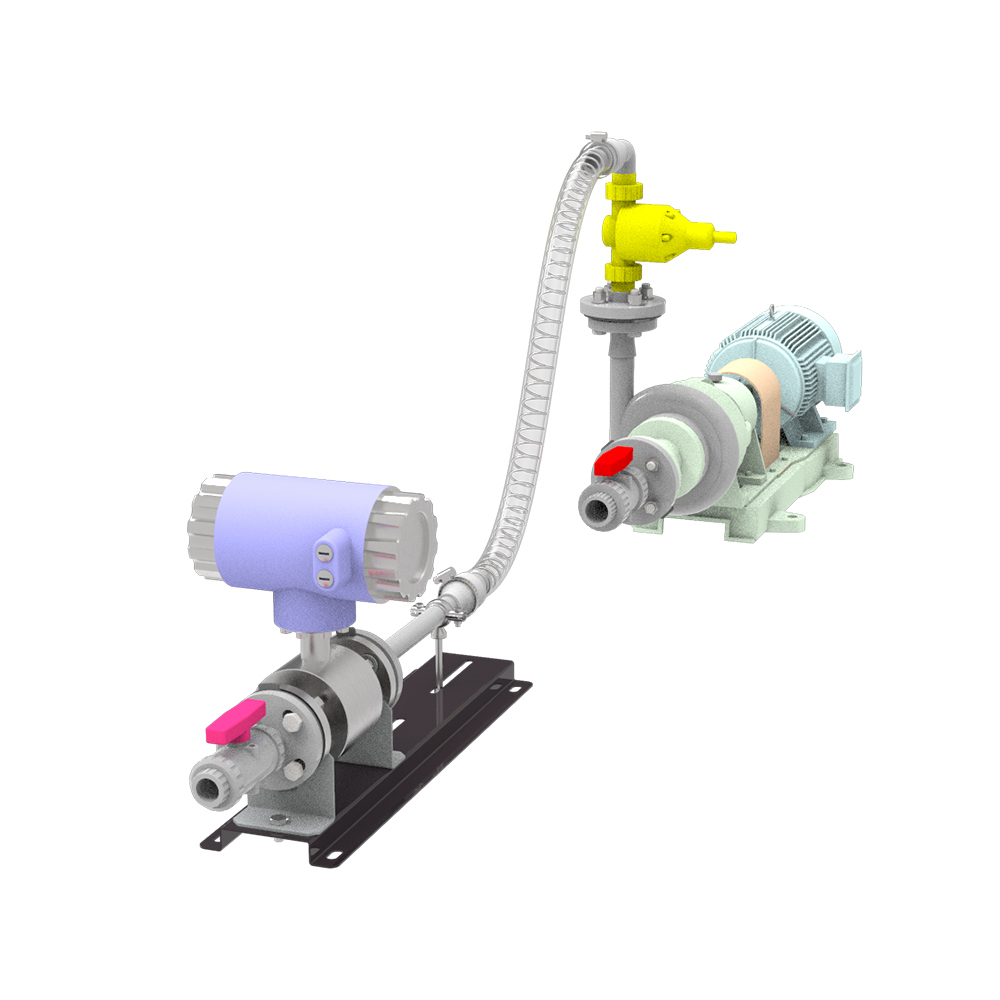

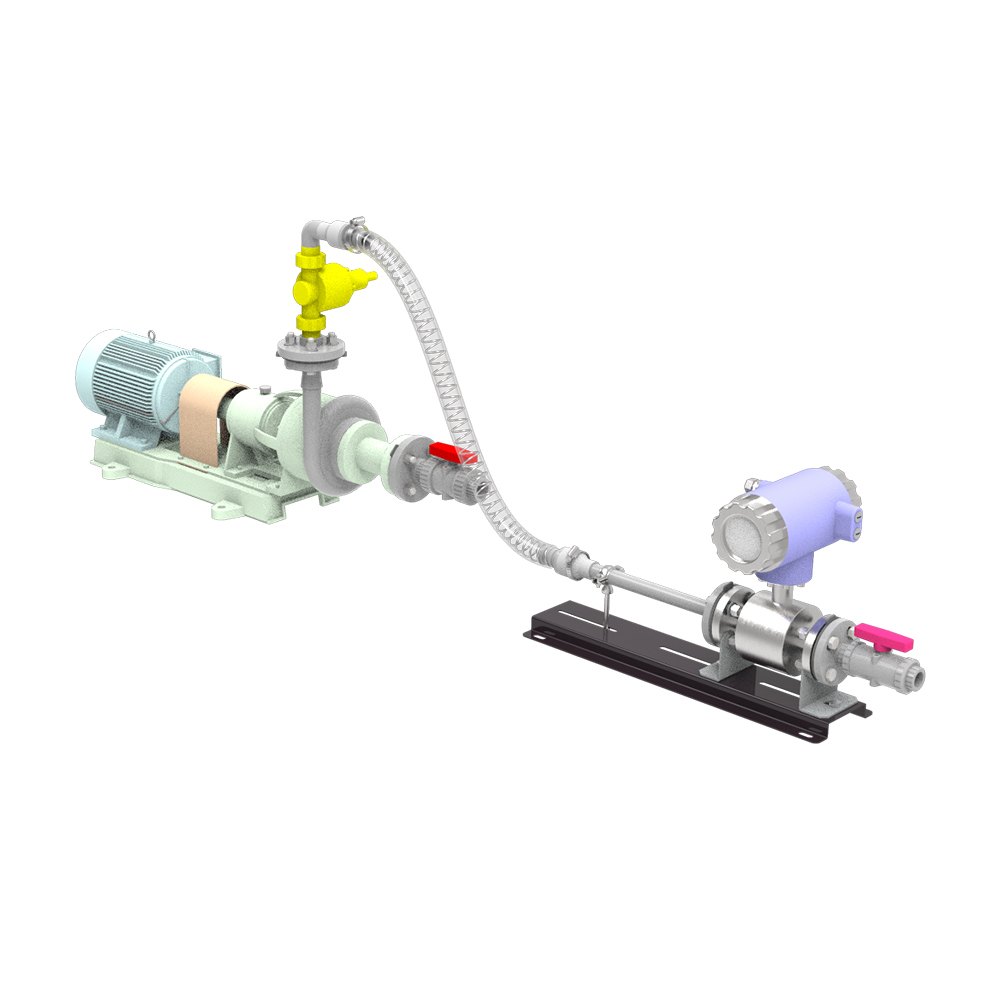

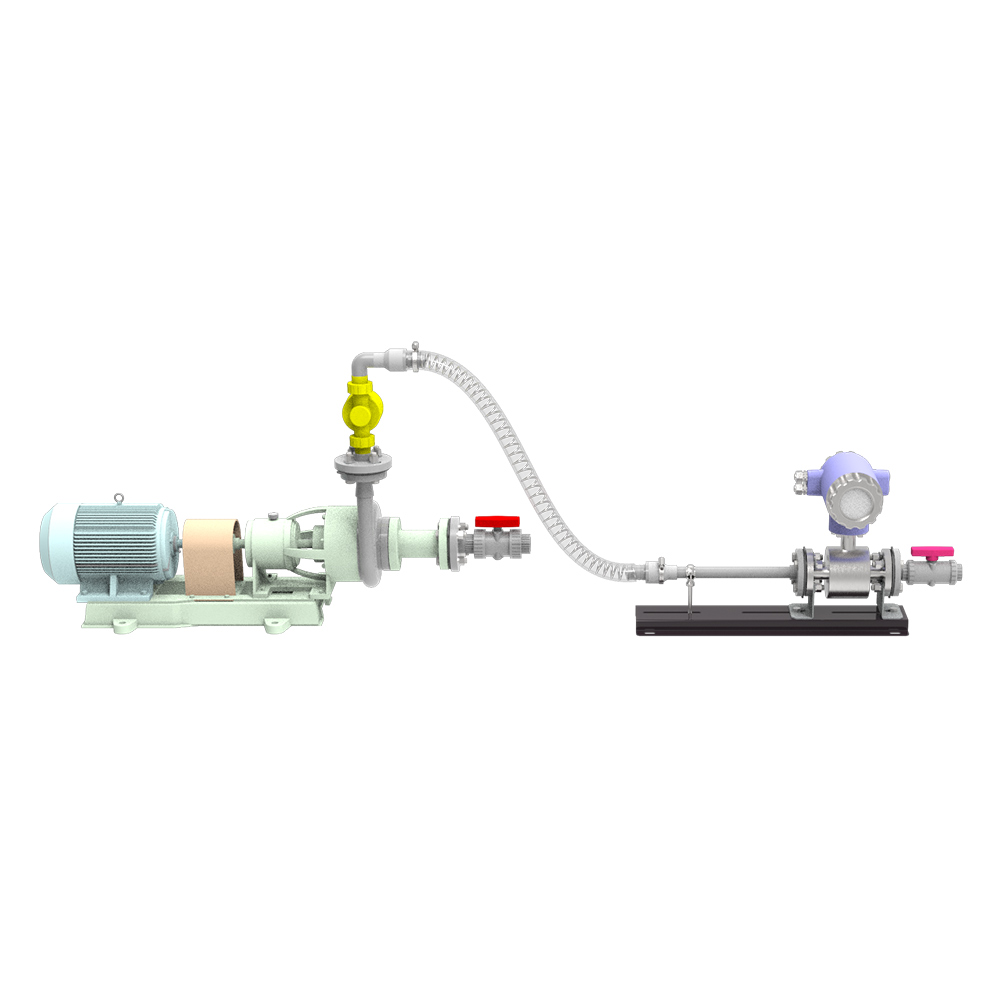

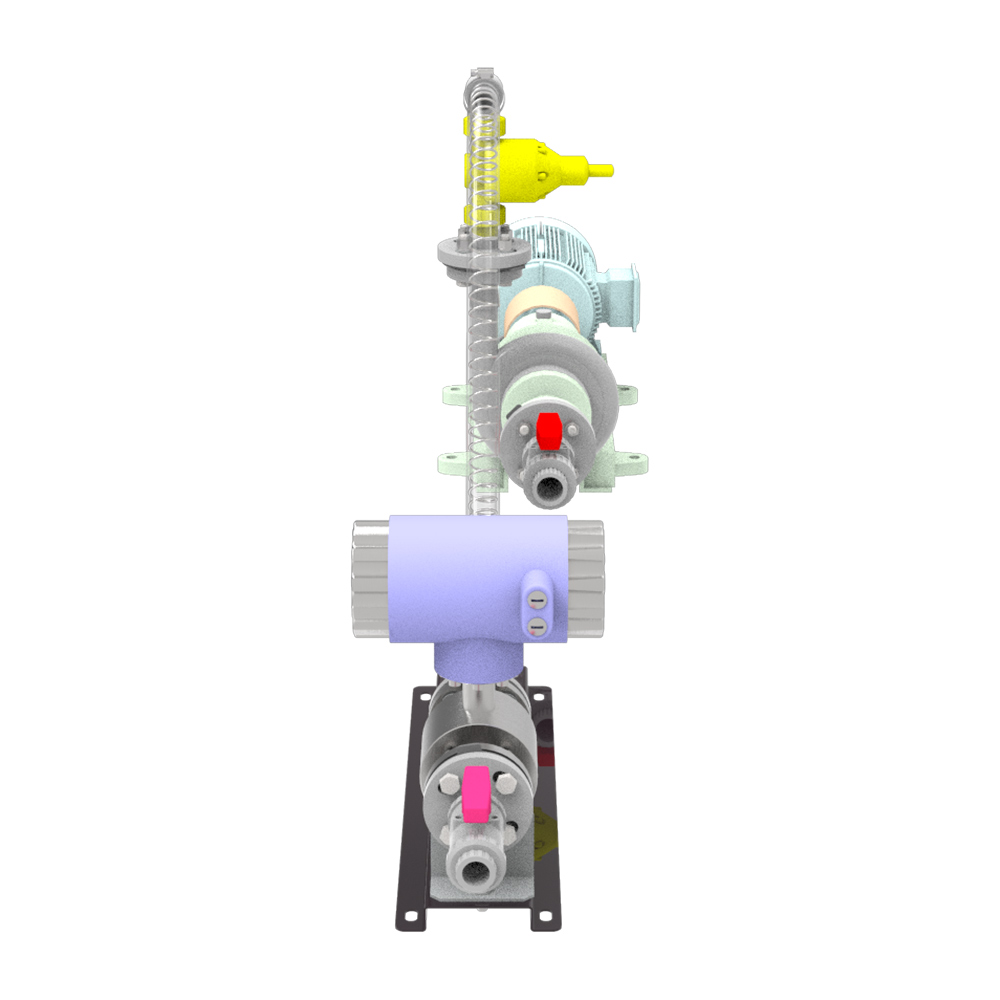

25FUH-30-3-20-C3

Chemical pumps are essential for transferring, dosing, and circulating a wide variety of corrosive or hazardous liquids in industrial applications. These pumps are specifically designed to handle aggressive chemicals such as acids, alkalis, solvents, and disinfectants, making them a critical component in sectors like water treatment, chemical processing, pharmaceuticals, and textile manufacturing. Whether used in continuous fluid transfer or precise metering operations, chemical pumps ensure reliable flow control while protecting systems and personnel from exposure to dangerous substances.

With options including corrosion-resistant materials, sealed designs, and various drive types—such as magnetic coupling or diaphragm actuation—chemical pumps offer both operational safety and chemical compatibility. Their versatility allows for integration into processes such as pH adjustment, chemical injection, fluid neutralization, and reagent mixing. By delivering consistent performance under challenging conditions, chemical pumps provide a robust, efficient, and low-maintenance solution for a broad range of demanding fluid handling tasks.

Chemical pumps are constructed using corrosion-resistant materials such as PTFE, PVDF, stainless steel, or high-performance plastics, depending on the chemical properties of the fluid being handled. Available in different types—including centrifugal pumps, magnetic drive pumps, diaphragm pumps, and peristaltic pumps—they offer a wide selection to suit flow rate, pressure, and application needs.

These pumps are designed to withstand challenging environments, including high temperatures, variable fluid concentrations, and the presence of solid particles or gas bubbles. In addition to fluid compatibility, chemical pumps often feature leak-proof or seal-less designs that enhance safety, especially when transporting toxic or volatile chemicals.

Product Advantages

1. Exceptional Chemical Resistance

Heavy Duty Chemical pumps can safely handle a wide range of aggressive media, including sulfuric acid, hydrochloric acid, nitric acid, sodium hydroxide, hydrogen peroxide, salt solutions, and organic solvents—across varying temperatures and concentrations.

2. Leak-Free Operation

Magnetic drive and diaphragm pumps eliminate the need for dynamic seals, preventing leaks and reducing maintenance risks. This makes them ideal for handling hazardous substances in critical environments.

3. High Precision and Flow Stability

Many chemical pump models support fine adjustment of flow rate and pressure, ensuring accurate dosing or fluid delivery. This is essential in applications where even small dosing errors could impact product quality or safety.

4. Low Maintenance and Long Service Life

With fewer moving parts in contact with the fluid, chemical pumps are engineered for durability. Their modular designs make parts easy to access and replace, minimizing downtime and lifecycle costs.

5. Easy Integration and Control

Chemical pumps can be integrated into automated control systems and configured to respond to flow sensors, pressure monitors, or programmable logic controllers (PLCs), enabling smart process control and remote operation.

Product Applications

Chemical pumps are used for a wide range of specific tasks within chemical handling processes. These include:

- Dosing and Metering: Accurate injection of acids, alkalis, or additives into a process stream for neutralization, pH control, or reaction balance.

- Chemical Transfer: Moving fluids between storage tanks, IBCs, and reactors without leaks or contamination.

- Circulation in Closed Systems: Ensuring consistent chemical flow in loops such as electroplating baths or chemical scrubbers.

- Batch Filling and Proportioning: Delivering measured quantities of fluids into mixing tanks or packaging units.

- Feeding Filtration and Treatment Systems: Pumping chemicals into filtration or ion exchange systems for water and fluid treatment.

The chemical pump is a reliable and versatile tool for managing aggressive, corrosive, or sensitive liquids with high levels of control and safety. Its robust design, chemical resistance, and leak-proof operation make it indispensable in industries such as chemical processing, water treatment, pharmaceuticals, food and beverage, new energy, and more. Whether used for precision dosing or bulk fluid transfer, a chemical pump ensures operational safety, efficiency, and long-term performance.