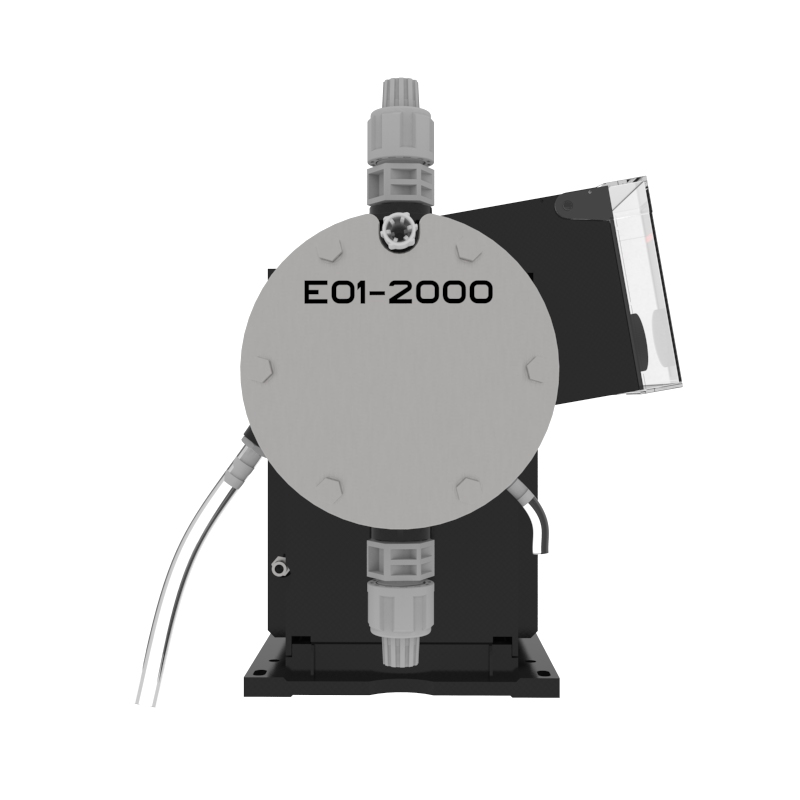

E01A 060-04

| TECHNICAL PROJECT | UNIT | E01A 060-04 |

| Turn-down ratio(Setting Range) | 1:X | 1:1000 |

| Maximum flow rate in standard mode | L/h | 60 |

| Maximum viscosity in 50% slow mode | L/h | 30 |

| Maximum viscosity in 25% slow mode | L/h | 15 |

| Minimum flow rate | L/h | 0.06 |

| Maximum operating pressure (Back Pressure) | Bar | 4 |

| Accuracy of repeatability | %FS | ±0.1~0.5 |

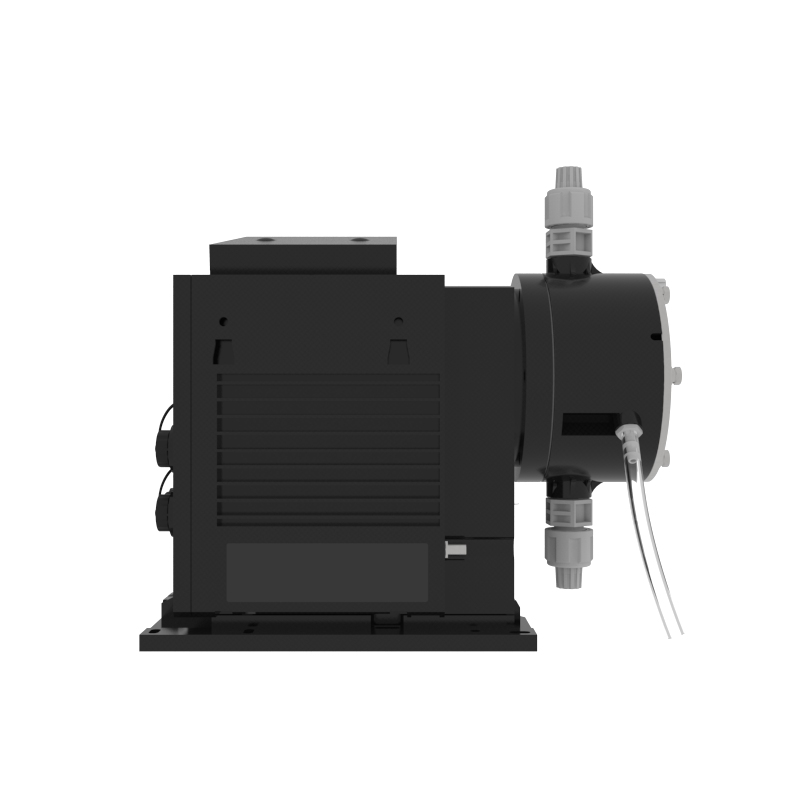

Our digital dosing pump is diaphragm metering pump driven by advanced algorithms(Huawei chip) and servo motors,so the precision of our pump is very high,within the error of 0.24%. It is very intelligent and full-automatic.

In addition, our digital metering pumps are equipped with YLC sensors, it is a pressure sensor, continuously monitor pipeline pressure, diaphragm status, bubble,pipeline blockage to promise high precision.If any abnormal condition appear,YLC sensor can send alarm display on the screen.(If the air come into the pipeline,we can set automatic exhaustion)

Key Features

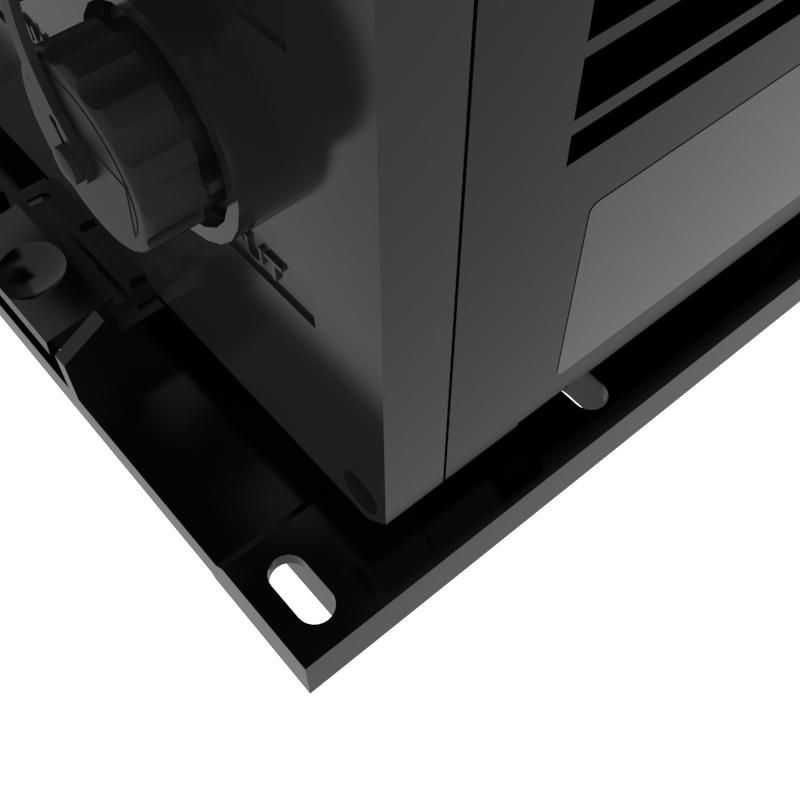

The Digital Dosing Pump System is engineered for users who value simplicity, speed, and precision. Designed with a fully modular structure, this pump offers quick installation and easy operation, reducing both labor and setup time. Whether in sewage treatment, chemical dosing, or industrial automation, this system integrates seamlessly into existing pipelines, ensuring minimal disruption and maximum productivity.

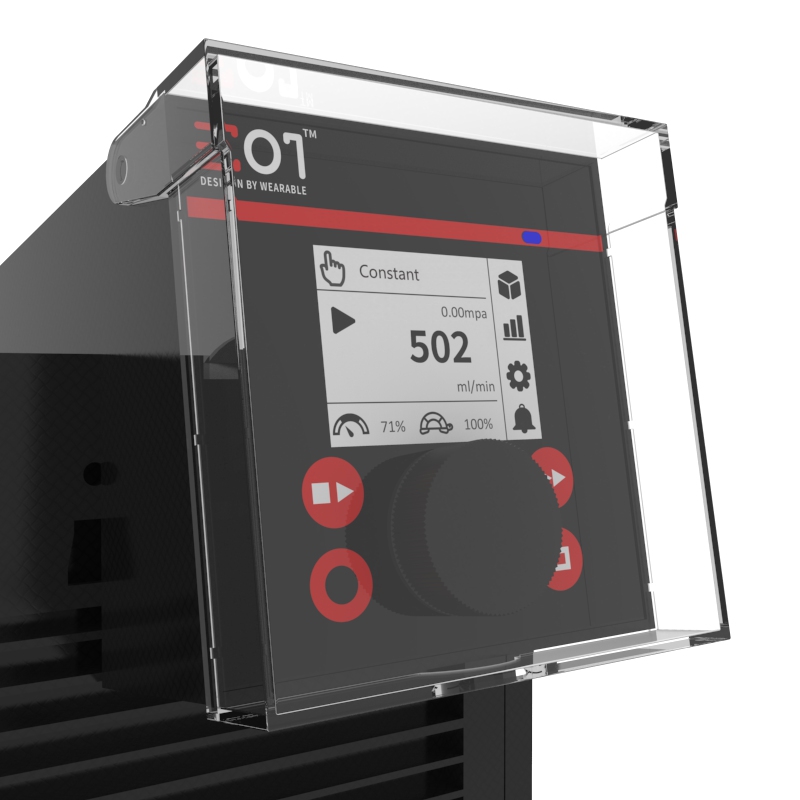

At the core of its performance is high-speed pulse control, enabling dosing resolutions up to 18,000 pulses per minute and achieving exceptional accuracy down to 0.296%. This high precision is matched by automated, intelligent control capabilities. Built-in AI algorithms support independent pH, liquid level, and concentration control—even without a PLC—allowing users to perform timing, quantitative delivery, and auto on/off functions with ease.

Ease of use is further enhanced by wireless functionality. With support for Wi-Fi and 4G, operators can remotely monitor and control the entire system via mobile phone. Real-time updates on flow rate, equipment status, cost reports, and wear-part life ensure that operations remain optimized and transparent.

To ensure long-term reliability, the pump is equipped with pipe network monitoring and anti-clogging features, including an integrated flushing function and multiple high-viscosity liquid handling strategies. Additionally, wear parts are designed for an extended service life, with built-in failure alerts for proactive maintenance.

With multiple external control options, condition monitoring, and versatile operating modes, this digital dosing solution is ideal for modern, intelligent fluid management. It brings together plug-and-play convenience with advanced automation, transforming complex metering tasks into streamlined, error-resistant operations.

Function:

Manual mode:It is the basic function ,You can set any flow rate you want through the control button,milliliter per minute. (press the button to start set and press it to finish)

Concentration mode:you can automatically proportion the concentration of dosing chemcial though this mode. It has three choices,the difference is precision higher(PPM million grade)Now we can enter into first one,you can set the original concentration of your liquid and the dilute concentration you want.

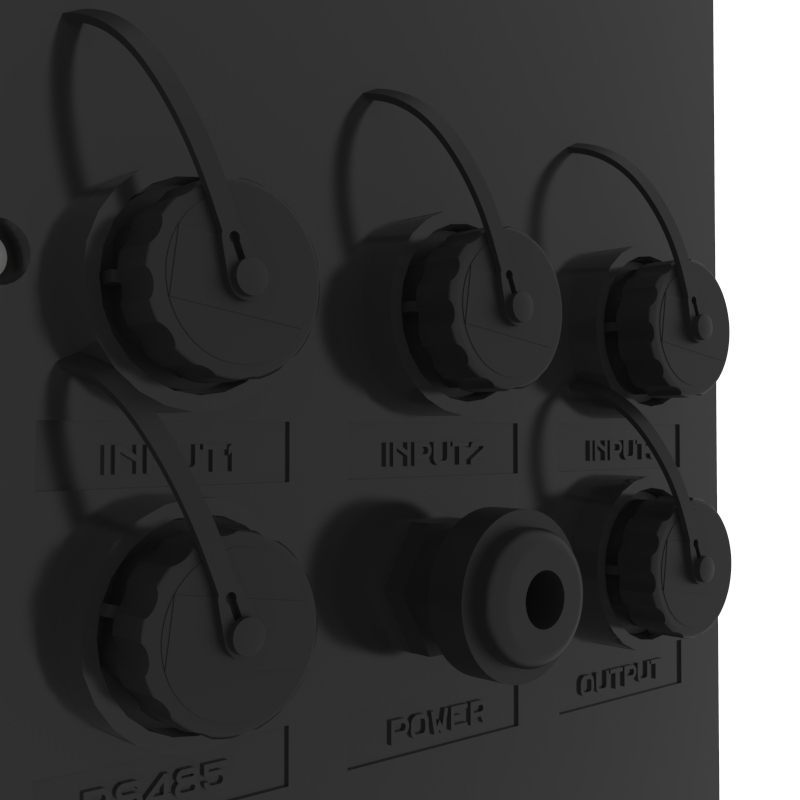

Impulse mode:In this mode,we can connect outside impulse signal though the interface input3,adjust the flow rate according to the impulse signal;if we set 1 milliliter/impulse signal,and we set 1 hz,the flow rate is 60 milliliter per minute.

Impulse control:It is always used for impulse water meter,our pump can automatically adjust the flow rate according to the flow rate change of impulse water meter.

Batch mode:you can set how much liquids you need to convey at one time

Current mode:0-20MA(milliampere)4-20MA

Pause-work:For example,you can set the working hours to 240minutes,and interval for 30 minutes,it means the pump will work for 4 hours and stop work for 30 minutes,when interval time over it will restart work (Cycle and continuous operation)according to the working time and intervals you set.

Weekly mode:You can set the start working time,continue working time(duration)and also the flow rate.You can set the maximum 20 in a week,from Monday to Sunday.

ROC mode:connect external control and start or stop the pump though the external button,digital control box

Marginal Notes

[1] Test results based on an altitude below 100 meters, using pure water as the medium at a temperature of 20°C

[2] Pressure differential can be increased by adding a back pressure valve to the outlet

[3]Optional flow components with different materials are available to extend the temperature range og the medium.For more details,please consult the manufacturer.