What Are Screw Pumps Used For?

Screw pumps are positive displacement pumps engineered to handle a variety of fluid types, including viscous, abrasive, and chemically aggressive media. Thanks to their robust structure and smooth-flow delivery, screw pumps are widely used for applications that require steady, non-pulsating flow and high volumetric efficiency.

One of the primary uses of screw pumps is chemical metering and transfer, especially in processes where fluid consistency and dosing precision are crucial. In systems like additive injection for energy production or color feeding in automotive manufacturing, screw pumps offer a stable and controlled flow even when the media is thick, sludgy, or corrosive.

In scale prevention and treatment systems, screw pumps deliver inhibitors, neutralizers, or disinfectants to water lines or cooling towers with high reliability. In addition, they are favored for feeding process additives in various industries—ensuring that reactions proceed optimally with minimal waste or contamination risk.

Another key area of application is chemical circulation in reactors or filtration units. The gentle action of screw pumps helps prevent shearing of sensitive compounds, which is especially important when handling polymers, enzymes, or biological agents.

Where Screw Pumps Are Used ?

Water and Wastewater Treatment Plants

Screw pumps are used to inject coagulants, disinfectants, and pH adjustment chemicals. Their precision makes them especially suitable for maintaining consistent water quality and regulatory compliance.

Automobile Manufacturing

In vehicle assembly plants, screw pumps are employed for feeding masterbatch materials during paint color mixing, ensuring even color distribution and formulation consistency.

New Energy Copper Foil Manufacturing

When producing copper foil used in batteries and other new energy technologies, accurate dosing of chemical additives is required. Screw pumps handle these tasks with precision, even at low flow rates.

Bio-Energy Production

The controlled delivery of enzyme additives is essential for bio-conversion processes. Screw pumps support consistent input of biological agents, reducing waste and enhancing system efficiency.

Chemical and Metallurgical Processing

In high-temperature or corrosive environments, such as acid dosing during smelting, screw pumps demonstrate exceptional material compatibility and operational stability.

Whether handling abrasive slurries in mineral beneficiation or fragile reagents in laboratory settings, screw pumps deliver dependable performance without compromising the composition or behavior of the fluid being processed.

How Do Screw Pumps Work?

Screw pumps operate using one or more rotating screws that move fluid along the axis of the screw shaft. As the screws turn, they create sealed cavities within the pump housing that trap and push fluid from the inlet to the outlet. This continuous displacement of fluid results in a smooth and stable flow that is largely free of pulsation or pressure spikes.

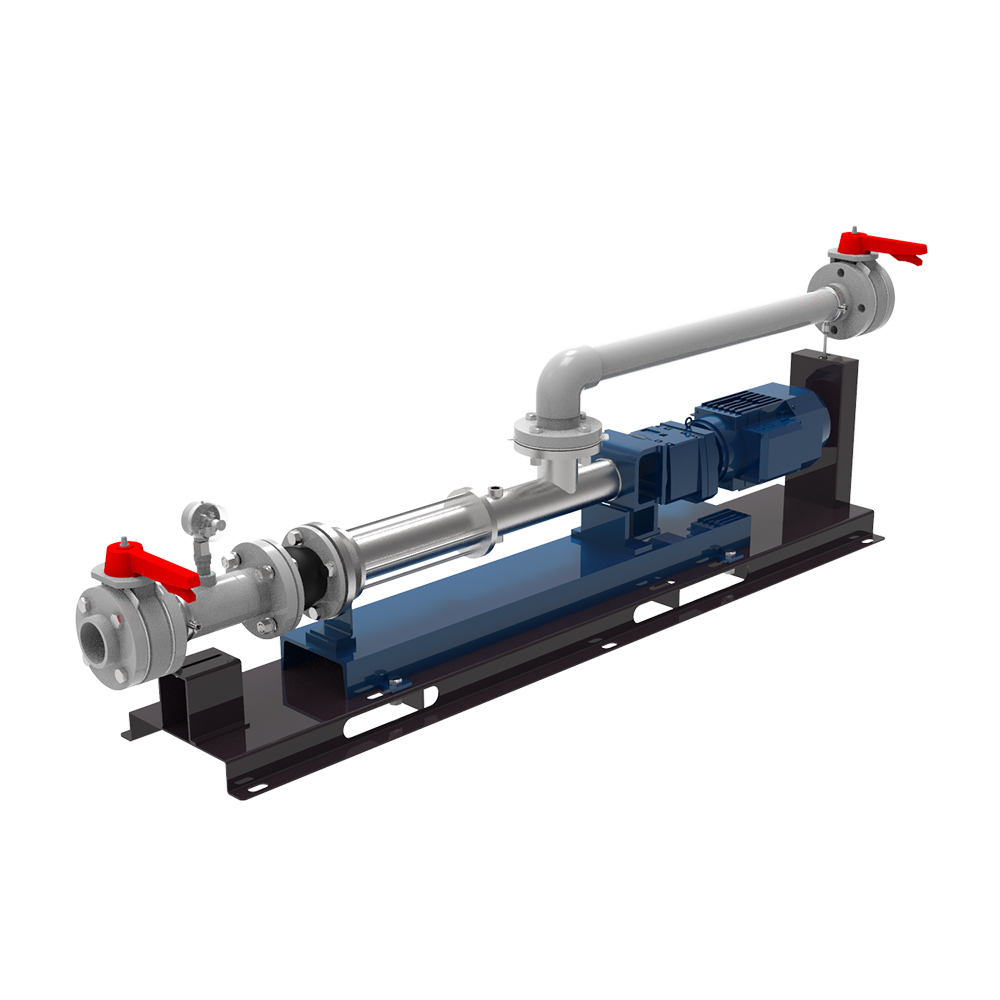

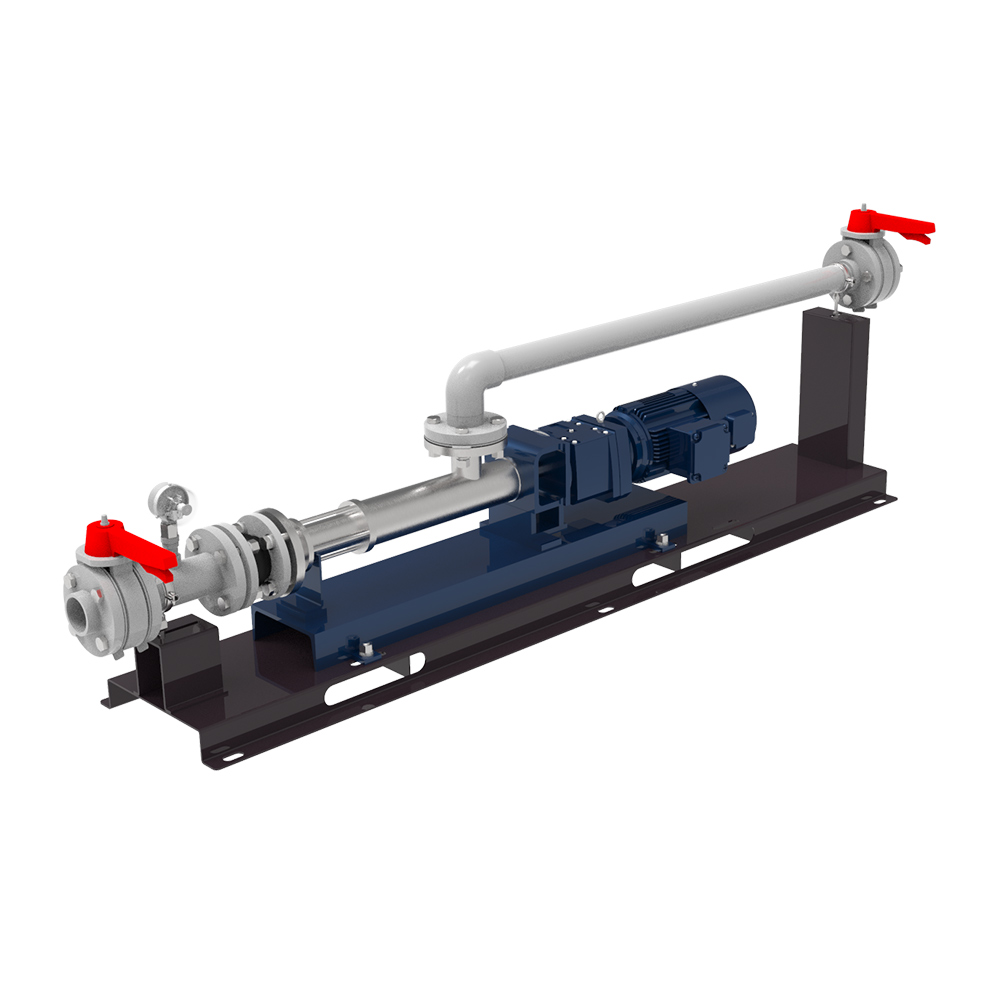

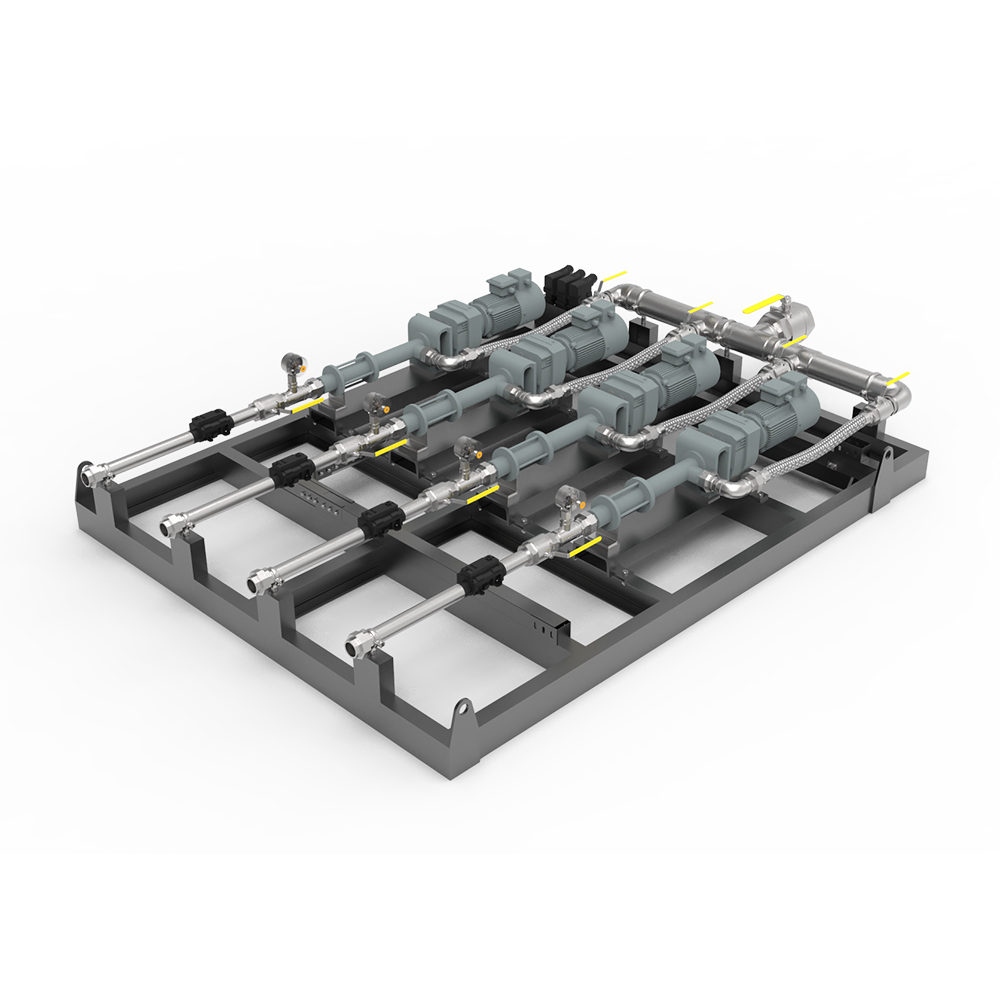

The design typically consists of either a single, twin, or triple-screw configuration, with each type offering specific advantages. Single-screw pumps are excellent for handling viscous and abrasive fluids at low flow rates. Twin and triple-screw pumps, on the other hand, are preferred for high-pressure systems requiring larger capacities and quieter operation.

Due to their robust design and simple mechanical movement, screw pumps experience less wear and have longer service lives compared to diaphragm or centrifugal pumps. Their ability to self-prime and maintain a constant flow under variable pressure conditions makes them an excellent fit for both batch and continuous flow systems.

Additionally, screw pumps can be integrated with sensors and automation controls to monitor pressure, flow rate, and fluid integrity. This enables predictive maintenance, minimizes manual intervention, and ensures uninterrupted operation even in complex processing environments.

Frequently Asked Questions

Q1: What materials are used in the pump construction?

A1: We use high-quality materials such as PTFE, PVC, and stainless steel to ensure durability and excellent resistance to chemical corrosion.

Q2: Can your pumps handle corrosive chemicals?

A2: Yes, our pumps are specifically designed to handle a wide range of corrosive and abrasive chemicals with high efficiency and long-term reliability.

Q3: Is your pump easy to maintain?

A3: Yes, our pumps are engineered for easy maintenance. The system provides alerts when components need replacement, and the process is user-friendly. For example, when replacing the diaphragm, simply press and hold the run-stop button, and the diaphragm will automatically pop out for quick replacement.