What Are Screw Pumps? Types, Applications, and Key Specs

Screw pumps, a type of rotary positive displacement rotary pumps, are well noted for their capacity to manage fluids that are highly viscous, abrasive, or chemically aggressive, while also providing high volumetric efficiency. They provide accurate, consistent, and pulse-free flow, making them useful in low noise and precision demanding applications. In this article, we will cover the operation of screw pumps, their main applications, and a type and performance parameters comparison for the various kinds of pumps.

What Is a Screw Pump?

A screw pump is composed of one or more screws which intermesh, and rotate within a casing that is tightly fitted. The rotation of the screws allows fluid to be trapped in the cavities formed by the screw threads and subsequently be transported in an axial manner from the suction side to the discharge side. The design minimizes slippage and ensures high efficiency, especially while dealing with viscous liquids.

A pump does not build up pressure on its own; it displaces the fluid with pressure and the back pressure is provided by the system (containing piping and valves). The manner in which screw pumps operate makes them energy efficient and applicable in a wide variety of situations.

Key Components of a Screw Pump

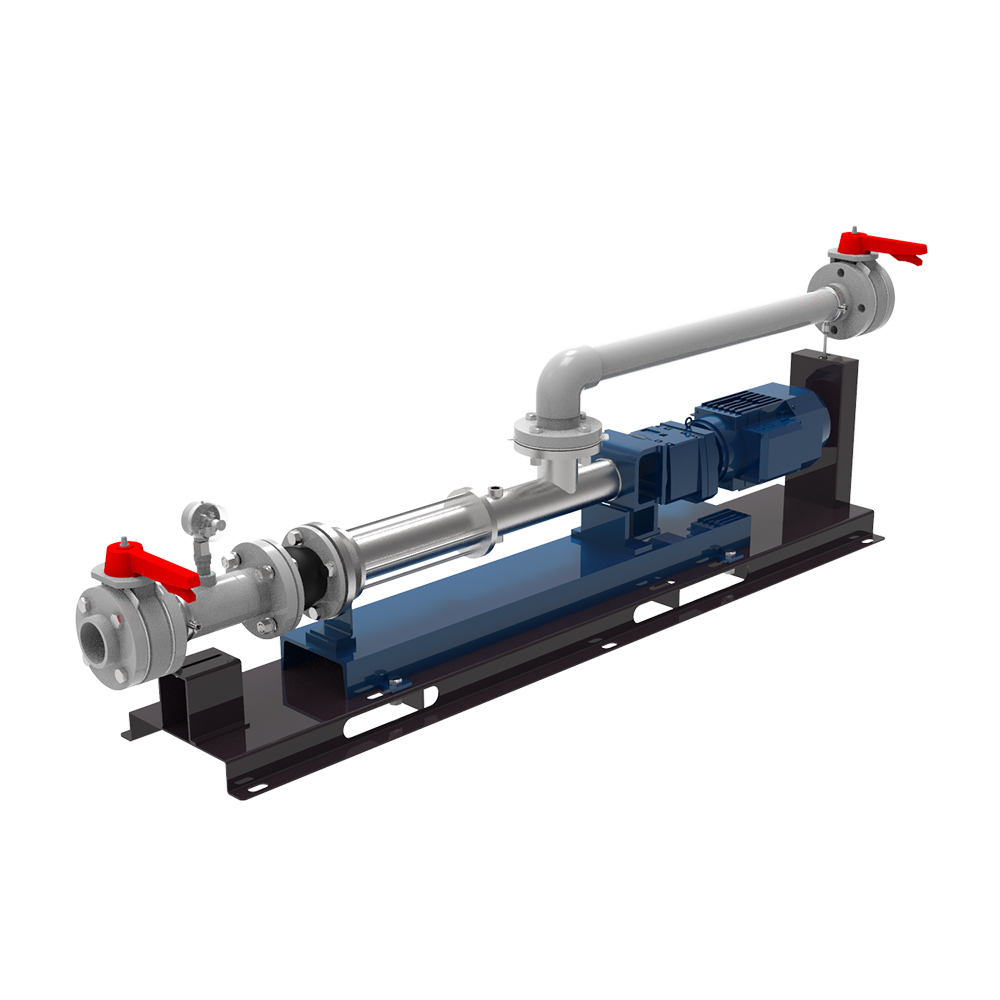

A typical screw pump includes:

Screw rotors: Can be single or multiple, depending on the type.

Pump casing: A precisely machined enclosure that houses the screw rotors.

Bearings and shaft: Ensure smooth rotation and transfer of torque.

Seals: Prevent leakage of fluid and contamination.

Drive unit: Usually an electric motor connected via a coupling or gear system.

How Do Screw Pumps Work?

A screw pump operates because a fluid is moved axially over the screw threads. Turns of the screw draw fluid into the formed cavities, and because of the forward movement of the screws, the fluid is pushed ahead. A non-pulsating flow, important for flow measurement and transfer, is maintained due to the continuous engagement of the screw threads.

High volumetric efficiency is achieved because the internal leakage due to “tight clearances” a pump’s part is precise. This geometry and accuracy is beneficial for high viscosity fluids and is a reason why centrifugal pumps often fail.

Applications of Screw Pumps

Screw pumps are versatile and serve numerous industries. Common applications include:

Chemical Processing: For dosing, circulation, and transfer of corrosive and viscous chemicals.

Oil and Gas: For transferring crude oil, lubricants, and polymer-based fluids.

Water and Wastewater Treatment: For feeding flocculants, coagulants, and pH adjusters.

Power Generation: In boiler feed systems and for dosing anti-scalants and conditioning agents.

Food and Beverage: For transferring syrups, sauces, and dairy products without damaging the fluid structure.

Automobile Manufacturing: For color masterbatch feeding and paint systems.

New Energy and Battery Materials: For precise chemical dosing in copper foil and lithium battery production.

Pulp and Paper: For pumping coatings, dyes, and paper additives.

Where Are Screw Pumps Used?

Screw pumps are employed in a variety of operational environments, including:

Industrial Plants (chemical, pharmaceutical, food processing)

In industrial production facilities—especially in sectors like chemical manufacturing, pharmaceuticals, and food processing—screw pumps are used for transferring both raw and processed fluids with high precision and consistency. Their ability to handle highly viscous, shear-sensitive, or even corrosive substances makes them ideal for moving syrups, oils, slurries, and even active pharmaceutical ingredients.

Municipal and Industrial Water Treatment Systems

In water and wastewater treatment systems, screw pumps are often used for chemical dosing, sludge transfer, and pH regulation. Their self-priming and clog-resistant capabilities allow them to handle raw sewage, thickened sludge, or coagulants like alum or ferric chloride. The pumps deliver consistent flow regardless of pressure fluctuations, helping treatment plants meet regulatory standards for clean water discharge while minimizing energy consumption and maintenance downtime.

Automotive Manufacturing Lines

Automotive production lines rely on screw pumps for a range of applications including lubricating oil transfer, paint supply, and feeding color masterbatches during mixing. Their ability to manage viscous fluids like synthetic resins and ensure a stable, bubble-free flow is essential for achieving consistent surface finishes and maintaining material uniformity across painted components. Additionally, screw pumps can be integrated into robotic assembly systems for precise, automated chemical feeding.

Metal and Non-Metal Mining Sites

Mining operations—both for metals and non-metallic minerals—require durable, high-capacity pumps for transferring abrasive slurries, chemical reagents, and dewatering fluids. Screw pumps are often chosen due to their resistance to wear and ability to handle solids-laden media without pulsation. In mineral flotation or leaching processes, screw pumps ensure a continuous flow of additives such as lime slurry or sulfuric acid, helping to optimize recovery rates while reducing downtime.

Their ability to handle shear-sensitive, high-viscosity, or corrosive fluids with minimal pulsation makes them indispensable in precision-driven applications.

Types of Screw Pumps

Screw pumps are broadly categorized into three main types, based on the number of screws used:

1. Single Screw Pumps (Progressive Cavity Pumps)

Use one rotor and an elastomeric stator.

Ideal for viscous, abrasive, or shear-sensitive fluids.

2. Twin Screw Pumps

Use two intermeshing screws.

Designed for high flow and moderate pressure applications.

Suitable for hygienic applications with CIP/SIP capability.

3. Triple Screw Pumps

Use a central drive screw and two idler screws.

Offer high pressure and compact footprint.

Used for lubricating oils and hydraulic systems.

Comparison of Screw Pump Types

| Feature | Single Screw Pump | Twin Screw Pump | Triple Screw Pump |

| Rotor Configuration | 1 rotor + 1 stator | 2 intermeshing rotors | 1 drive + 2 idler screws |

| Fluid Type | Viscous, abrasive | Clean to moderately viscous | Lubricants, clean fluids |

| Pressure Range | Up to 24 bar | Up to 30 bar | Up to 100 bar |

| Flow Pulsation | Low | Very low | Very low |

| Maintenance | Moderate | Easy (CIP capable) | Low |

| Typical Application | Wastewater, food, cosmetics | Oil, food, chemicals | Lube oil, fuel injection |

Performance Parameters

The suitability of a screw pump for any application depends on a variety of performance metrics, including:

Flow Rate: Screw pumps can handle wide flow ranges, from a few liters per hour to hundreds of cubic meters per hour.

Pressure Capacity: These pumps can typically deliver up to 100 bar depending on the screw configuration.

Viscosity Range: Screw pumps excel at handling high-viscosity fluids (up to 1,000,000 cP or more).

Temperature Tolerance: Many screw pumps can operate up to 350°C depending on the material of construction.

Performance Parameters of Screw Pump Types

| Parameter | Single Screw Pump | Twin Screw Pump | Triple Screw Pump |

| Flow Rate Range | 0.1 to 300 m³/h | 1 to 500 m³/h | 5 to 1000 m³/h |

| Viscosity Range | Up to 1,000,000 cP | 1 to 100,000 cP | 1 to 5,000 cP |

| Pressure Capability | Up to 24 bar | Up to 30 bar | Up to 100 bar |

| Max Temperature | 150℃ | 250℃ | 350℃ |

Benefits of Screw Pumps

Non-Pulsating Flow: Ensures consistent pressure and smooth operation.

High Efficiency: Minimal internal leakage even with viscous media.

Low Noise and Vibration: Especially useful in laboratory and cleanroom settings.

Self-Priming and Reversible: Flexible for complex system requirements.

Excellent Suction Capability: Suitable for suction lift applications.

Durable with Low Maintenance: Extended service life in continuous operations.

Screw pumps are a reliable and versatile solution for fluid transfer in industrial applications where precision, efficiency, and durability are critical. From dosing corrosive chemicals to transporting viscous slurries, their adaptability across industries and conditions makes them an essential part of modern process engineering. By choosing the right type of screw pump and understanding its performance capabilities, users can achieve optimal results while reducing downtime and maintenance costs.