What’s the Difference Between Single, Twin, and Triple Screw Pumps?

Screw pumps have long been a staple in fluid transfer systems for their efficiency, reliability, and ability to handle a wide range of viscosities and pressures. Among the various types, single, twin, and triple screw pumps are most commonly used in industrial applications. Understanding the structural differences, performance characteristics, advantages, limitations, and ideal applications of each type is essential for selecting the right pump for your system.

Overview of Screw Pump Technology

Screw pumps are rotary, positive displacement pumps that use one or more intermeshing screws to move fluid along the screw axis. Their smooth, continuous flow, ability to handle high-viscosity fluids, and minimal pulsation make them suitable for applications across oil & gas, marine, chemical, food processing, and power generation sectors.

Each variant—single, twin, and triple screw—offers different mechanical designs and operational strengths.

| Pump Type | Number of Screws | Flow Characteristics | Typical Viscosity Range |

| Single Screw | 1 (with stator) | Pulsation-free, steady | Low to high |

| Twin Screw | 2 (counter-rotating) | Gentle, non-pulsating | Medium to high |

| Triple Screw | 3 (one drive, two idlers) | Smooth, continuous | Low to medium |

Single Screw Pumps

Single screw pumps, also referred to as progressive cavity pumps, are positive displacement pumps known for their ability to handle viscous and sensitive fluids with minimal shear.

Advantages

1. Superior Handling of High-Viscosity Fluids

One of the defining strengths of single screw pumps is their capacity to manage highly viscous, non-Newtonian fluids such as sludges, pastes, thick oils, and slurries. Because of the progressive cavity design, these pumps can transport fluids with viscosities exceeding 1,000,000 cP without compromising flow consistency.

2. Self-Priming and Dry-Running Capabilities

Single screw pumps can self-prime, which means they can evacuate air from the suction line and begin pumping without pre-filling the inlet. This makes them ideal for intermittent or start-stop operations in challenging environments.

3. Low Pulsation and Shear

The continuous cavity movement ensures a near pulse-free flow, which reduces mechanical stress on connected systems like dosing valves, filtration membranes, and delicate instruments. The gentle transfer also minimizes shear forces, preserving the structural integrity of sensitive fluids such as polymer emulsions, dairy products, or live-cell suspensions.

4. Quiet Operation with Low Vibration

Due to their smooth rotational motion, single screw pumps operate with low noise levels and minimal vibration, making them suitable for noise-sensitive settings such as food processing facilities, laboratories, or pharmaceutical plants.

Limitations

1. Wear and Tear on Elastomeric Stator

The stator, being made of rubber or similar flexible materials, is prone to wear—especially when abrasive particles, harsh solvents, or high-temperature fluids are involved.

2. Pressure Limitations

While suitable for low- to moderate-pressure applications, single screw pumps generally offer lower discharge pressures compared to twin or triple screw pumps. This restricts their use in high-pressure process lines or long-distance fluid transfer systems.

3. Relatively Slower Speeds

To protect internal components and reduce wear, these pumps operate at lower rotational speeds.

Common Applications

Due to their versatility and ability to manage challenging fluids, single screw pumps are widely used across many industries:

Wastewater Treatment: Ideal for transporting sludge, bio-solids, and other semi-solid waste in sewage processing and municipal plants.

Food & Beverage Processing: Used for pumping viscous products like yogurt, dough, peanut butter, syrups, and fruit pastes. The low shear design ensures product quality and texture are preserved.

Chemical Industry: Commonly used in chemical dosing and transfer systems, particularly for adhesives, polymers, and additives.

Twin Screw Pumps

Unlike single screw pumps that rely on an elastomeric stator, twin screw pumps use metallic rotors, making them suitable for more demanding industrial applications where durability and high-pressure capabilities are essential. The screws rotate synchronously, creating sealed chambers that move fluid steadily from the inlet to the outlet without pulsation or turbulence.

Advantages

1. High Pressure and Flow Stability

Twin screw pumps can operate at significantly higher pressures compared to single screw pumps. The robust rotor design allows them to handle discharge pressures well beyond 10 bar (145 psi) without sacrificing flow stability. This makes them suitable for high-pressure dosing and transfer applications in complex process systems.

2. Broad Fluid Compatibility

Thanks to metallic rotors and the absence of elastomeric components in the pumping chamber, twin screw pumps can tolerate a wide variety of fluids including corrosive chemicals, abrasive slurries, and high-temperature liquids. Their mechanical seal designs are optimized to maintain integrity in harsh chemical environments.

3. Pulsation-Free, Low Shear Flow

The intermeshing screws provide a nearly pulsation-free flow with very low shear forces, making twin screw pumps ideal for transporting shear-sensitive fluids such as emulsions, polymers, and food products. This characteristic also helps prevent foaming and degradation in sensitive materials.

4. Self-Priming and Dry Running Capability

Twin screw pumps excel in self-priming applications and can handle entrained gases or vapors without losing prime. Some designs also support limited dry running, which increases operational flexibility during maintenance or process interruptions.

Limitations

1. Higher Initial Cost

Compared to single screw pumps, twin screw pumps generally involve higher capital investment due to more complex machining and the use of metal rotors and seals.

2. Size and Weight

The robust construction and metal components result in a heavier and bulkier pump design. This can limit their use in compact installations or mobile systems where space and weight are constraints.

3. Maintenance Complexity

Although durable, twin screw pumps require precise alignment of the rotors and careful maintenance of mechanical seals. Repair and overhaul may demand skilled technicians and specialized tools.

Common Applications

Twin screw pumps are widely used in industries that require reliable, high-pressure fluid handling with minimal pulsation and shear:

Chemical and Petrochemical Processing: Ideal for transferring corrosive acids, solvents, and viscous chemicals under controlled flow and pressure.

Metallurgy and Smelting: Used for dosing acid additives and handling abrasive slurries in metal refining and ore processing.

Industrial Cooling Systems: Employed in the injection of scale inhibitors and corrosion inhibitors to ensure equipment longevity.

Wastewater and Sewage Treatment: Effective for chemical dosing and sludge transfer where pulsation-free flow reduces stress on treatment components.

New Energy Manufacturing: Used for precise additive dosing in copper foil production for batteries, helping maintain product quality and consistency.

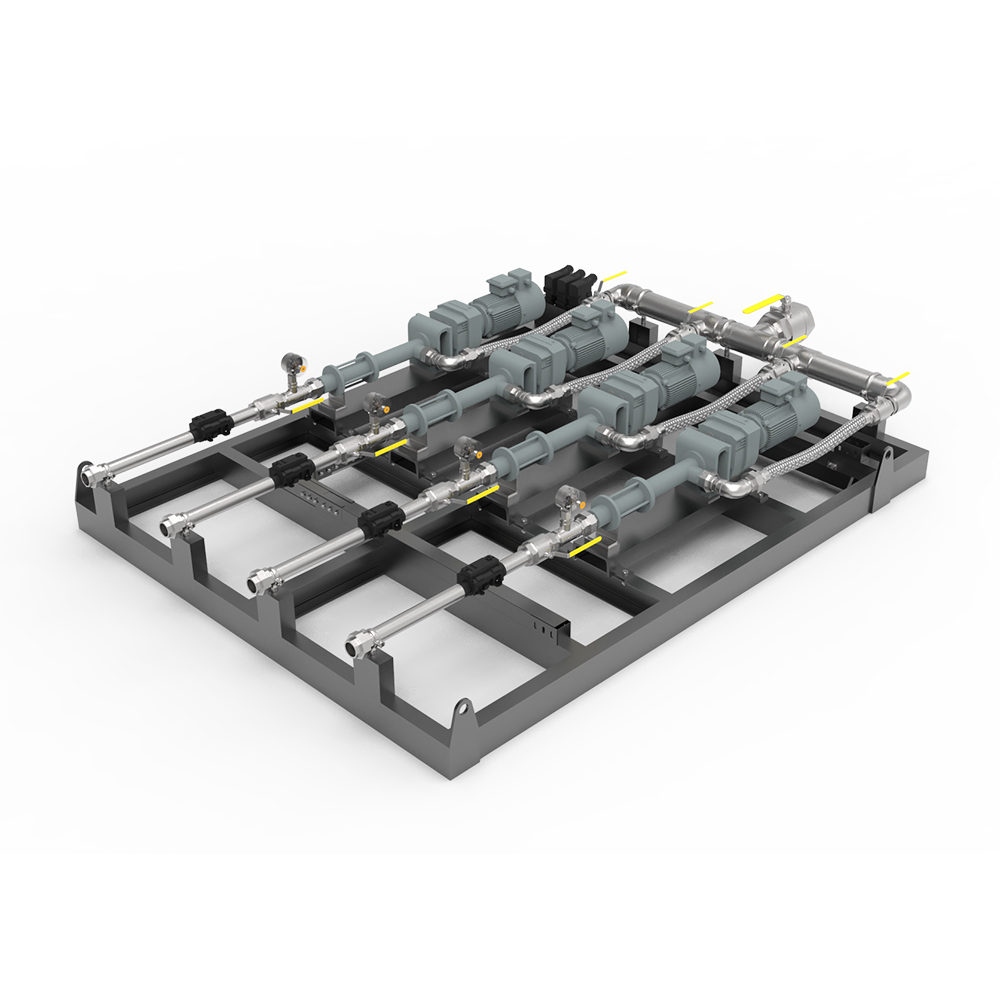

Triple Screw Pumps

Triple screw pumps are a subtype of positive displacement rotary pumps that use three intermeshing screws to move fluid in a continuous, axial flow. The central driving screw (power rotor) meshes with two driven screws (idler rotors), forming sealed chambers that push fluid smoothly from the suction side to the discharge.

Advantages

1. High Pressure Capability

One of the key advantages of triple screw pumps is their ability to generate very high discharge pressures, often exceeding 100 bar (1,450 psi), depending on the design. This makes them suitable for heavy-duty industrial systems like hydraulic power units, high-pressure fuel injection, and lubrication circuits in large rotating equipment.

2. Smooth, Pulse-Free Flow

Thanks to the continuous engagement of the three screws and their axial flow mechanism, triple screw pumps produce virtually no pulsation or turbulence. This ensures consistent flow and minimizes vibration and noise—ideal for systems with strict performance or acoustic requirements.

3. Excellent Efficiency with Lubricating Fluids

These pumps are most effective when used with clean, low- to medium-viscosity lubricating fluids such as fuel oils, hydraulic fluids, and synthetic oils. Their internal clearances and metal-to-metal sealing are optimized to maintain high volumetric efficiency in such conditions.

4. Compact and Reliable Design

Triple screw pumps are typically more compact than multi-stage centrifugal pumps for equivalent pressure ranges. With fewer moving parts and a balanced load distribution across the screws, they offer long service life and reduced maintenance demands when operating under proper conditions.

5. Wide Temperature Tolerance

With appropriate materials and sealing arrangements, triple screw pumps can handle fluids at extreme temperatures, ranging from -30°C to over 200°C, making them suitable for thermal oil and power generation systems.

Limitations

1. Sensitivity to Fluid Cleanliness

Triple screw pumps require clean, non-abrasive fluids for optimal performance. Contaminants like sand, rust, or particulates can rapidly wear down screw surfaces and internal clearances, leading to leakage or reduced efficiency.

2. Limited Suitability for High-Viscosity or Non-Lubricating Fluids

These pumps are not ideal for highly viscous, shear-sensitive, or non-lubricating fluids such as sludge, slurries, or emulsions. Viscous resistance can interfere with the precise operation of the screw elements, resulting in excess wear or energy consumption.

3. High Initial Cost and Tight Tolerances

Due to the need for precision machining and durable materials, triple screw pumps tend to have higher initial costs. Moreover, their narrow clearances demand exacting installation and operating conditions, limiting flexibility in variable environments.

Common Applications

Triple screw pumps are widely used in applications that demand high pressure, stable flow, and clean fluid operation. Typical sectors include:

Power Generation: Used for fuel oil transfer, boiler feed, and lubrication of turbines and generators.

Hydraulic Systems: Frequently found in high-pressure hydraulic power units (HPUs) for industrial and mobile equipment.

Thermal Oil Circulation: Suited for systems requiring precise thermal fluid control, such as mold temperature control or heat exchangers.

Compressor and Gearbox Lubrication: Triple screw pumps deliver stable lubrication to rotating machinery under high-pressure conditions.

| Feature / Type | Single Screw | Twin Screw | Triple Screw |

| Max Pressure | \~12 bar | \~25-30 bar | \~310 bar (4500 psi) |

| Viscosity Range (cSt) | Up to 1,000,000 | 0.3 - 1,000,000 | 1-2,000 |

| Abrasive Handling | Fair | Good | Poor |

| Gas Handling | Good | Excellent | Poor |

| Shear Sensitivity | Excellent | Good | Moderate |

| Maintenance Level | Moderate | High | Low |

Choosing the Right Screw Pump

When selecting between single, twin, and triple screw pumps, consider the following parameters:

Viscosity of the fluid: Single screw for thick sludges, triple screw for lubricants.

Presence of solids/gases: Twin screw handles multiphase flow best.

Pressure requirements: Triple screw pumps offer the highest pressure.

Hygienic standards: Twin screw pumps can comply with FDA, 3A standards.

Operational cost vs. performance needs: Balance complexity and long-term benefits.

In general:

Use single screw for abrasive, shear-sensitive, or highly viscous fluids.

Use twin screw for multi-purpose applications requiring wide flexibility.

Use triple screw for clean, lubricating fluids under high-pressure conditions.

Screw pumps are versatile and efficient tools for fluid transfer, but each type comes with distinct characteristics. Whether you're managing wastewater, transferring crude oil, or circulating lubricating oil, understanding the mechanical differences between single, twin, and triple screw pumps helps optimize performance, reduce maintenance, and meet process-specific needs. Carefully evaluating your application against the advantages and limitations outlined in this article will guide you toward the best-fit solution.