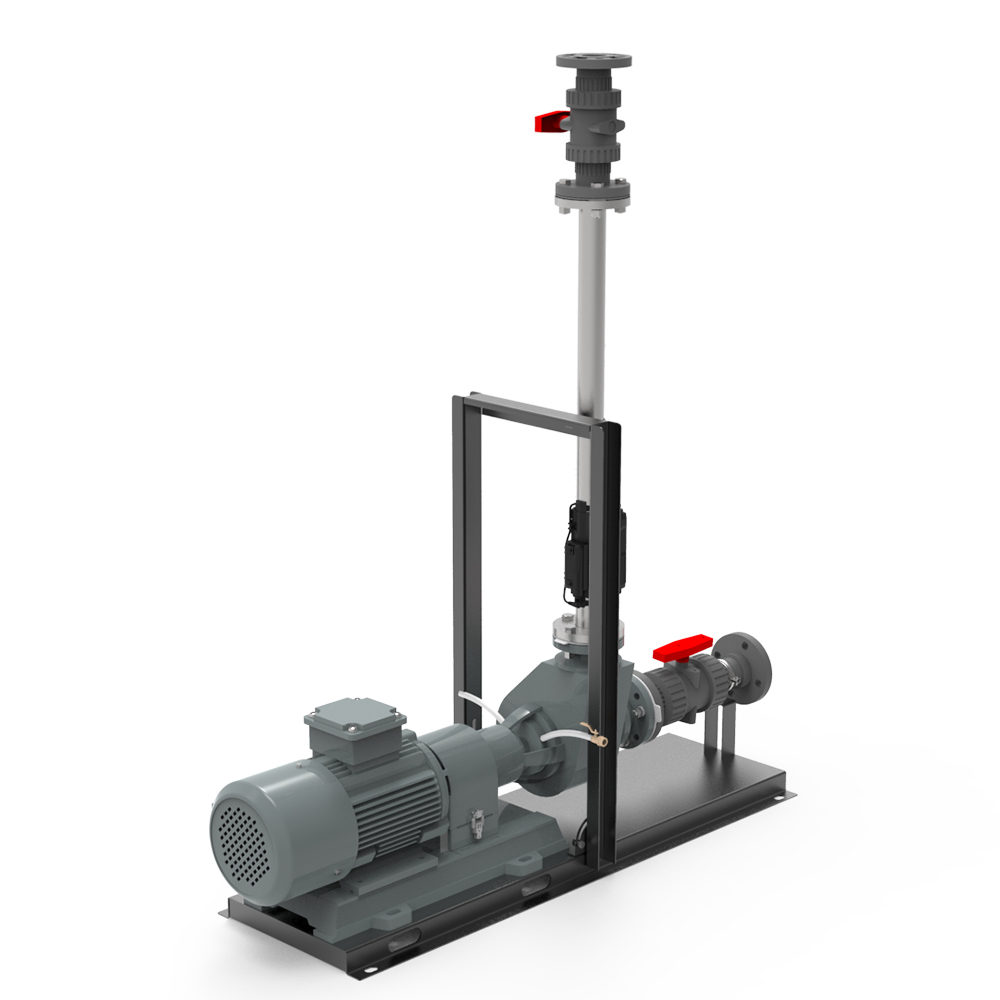

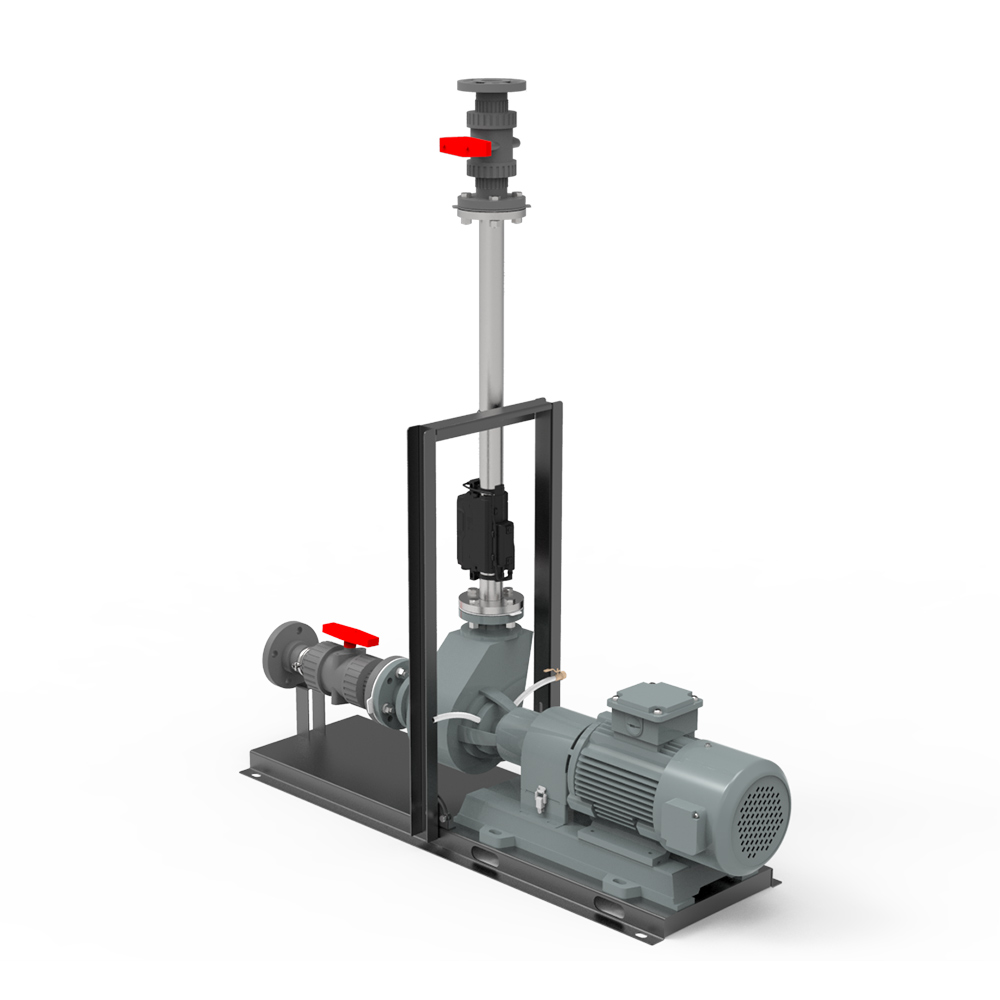

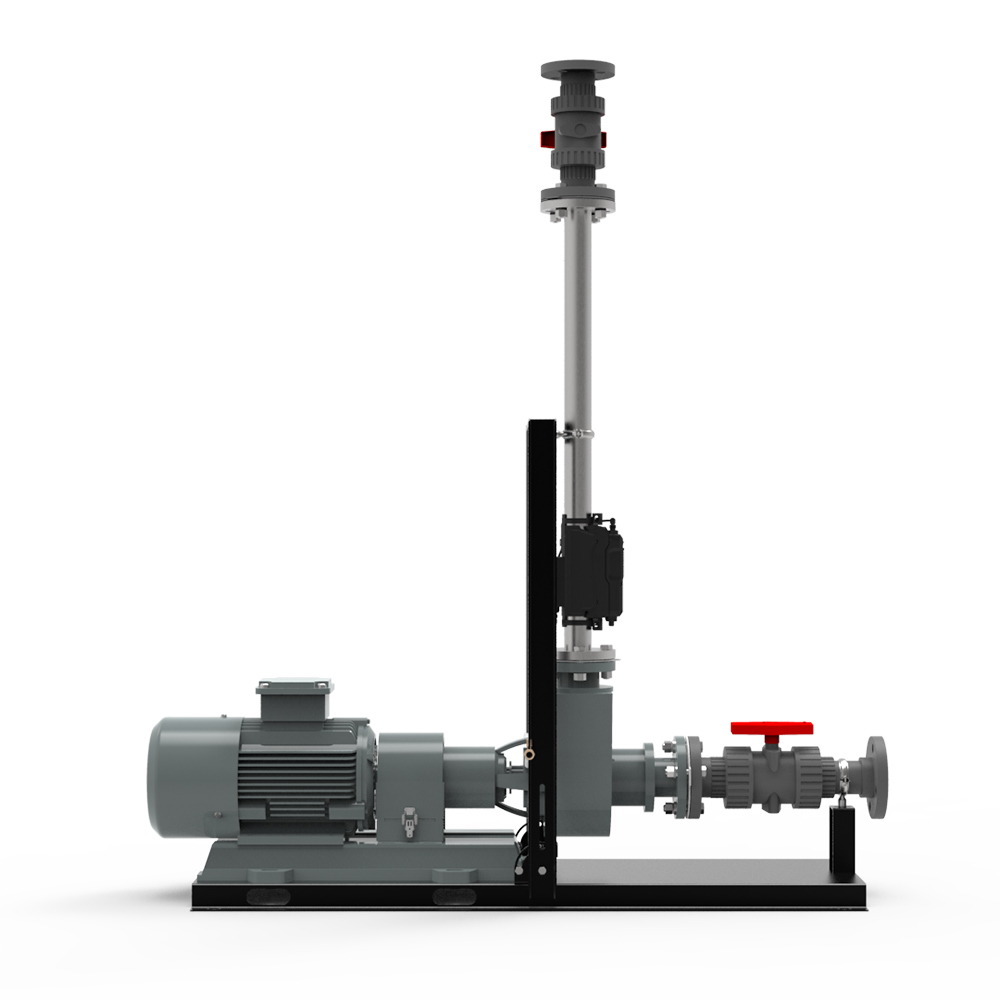

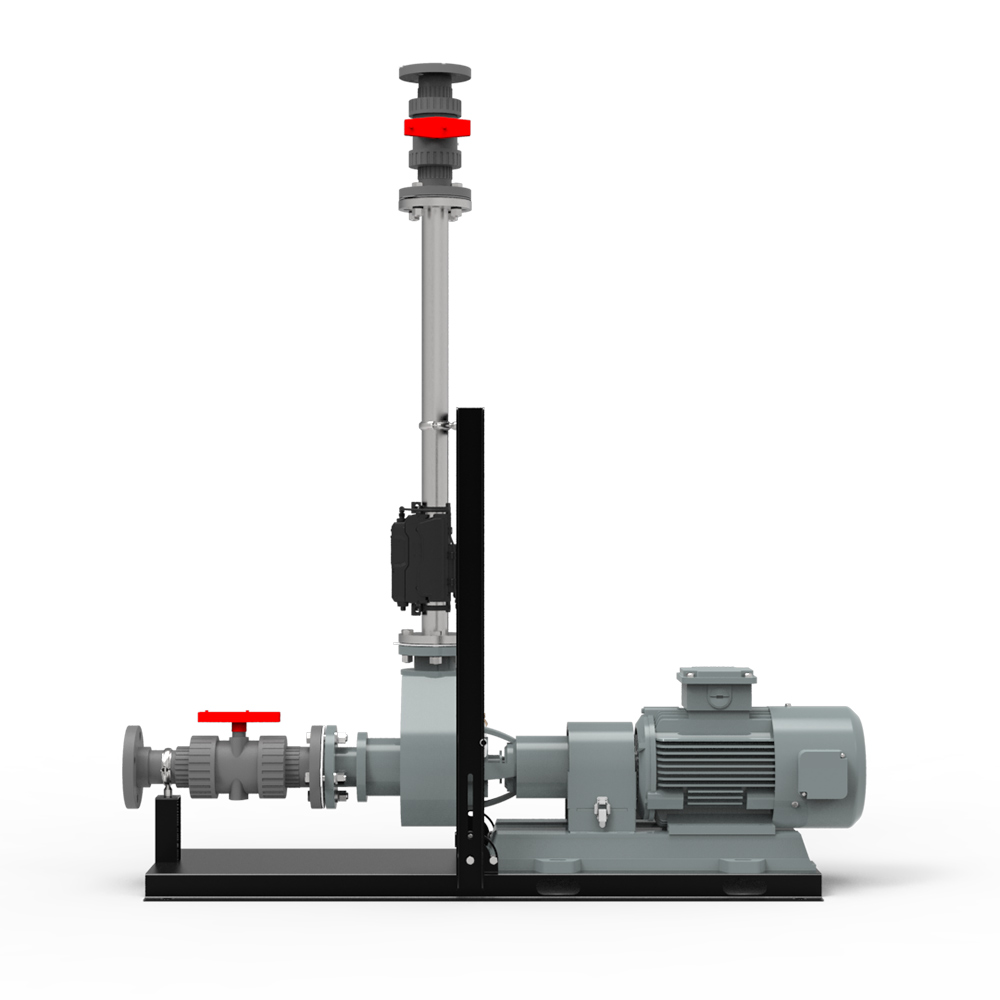

65FUH-30-21.64-30-C3

Chemical pumps are designed to safely transfer, dose, and circulate corrosive or hazardous liquids such as acids, alkalis, and solvents. Widely used in water treatment, chemical processing, pharmaceuticals, and textiles, they ensure precise flow control while protecting equipment and operators. Featuring corrosion-resistant materials, sealed constructions, and drive options like magnetic coupling or diaphragm actuation, chemical pumps support applications including chemical injection, pH control, and reagent mixing. Their reliable performance under harsh conditions makes them an efficient, durable, and low-maintenance solution for demanding industrial fluid handling.

A chemical pump is a specialized industrial pump designed to handle aggressive, corrosive, or hazardous fluids with high reliability and efficiency. Whether transporting strong acids, alkalis, solvents, or chemically reactive compounds, chemical pumps ensure safe fluid transfer while maintaining system integrity. These pumps are vital in industries where the purity, stability, and safety of chemical media are non-negotiable.

They are engineered to handle both low- and high-temperature liquids, as well as fluids that may contain abrasive particles or require sanitary processing. Available in several configurations—such as centrifugal pumps, magnetic drive pumps, and diaphragm pumps—chemical pumps are selected based on flow rate, pressure, chemical compatibility, and system requirements.

Product Advantages

1. Excellent Chemical Compatibility

Chemical Process Pumps can handle a wide range of substances, including inorganic acids (like sulfuric, hydrochloric, and nitric acid), alkaline solutions (such as sodium hydroxide), oxidizing agents, petrochemicals, salt solutions, and organic compounds.

2. High Safety Standards

Many chemical pumps feature leak-free designs using magnetic drive or diaphragm mechanisms, which eliminate the need for dynamic seals. This greatly reduces the risk of fluid leakage and operator exposure.

3. Durable and Corrosion-Resistant Construction

Made with high-performance materials, chemical pumps resist wear and corrosion even in highly reactive or abrasive environments. This extends service life and reduces maintenance costs.

4. Stable Performance and Precise Flow

With smooth, continuous operation and consistent flow rates, chemical pumps support precise dosing and fluid delivery. Some models offer flow monitoring and control capabilities to ensure accuracy in demanding processes.

5. Easy Maintenance and Integration

Modular designs and accessible parts make maintenance straightforward. Chemical pumps can be easily integrated into automated systems and paired with sensors, controllers, or monitoring devices.

Product Application

Chemical pumps are engineered for precise, safe, and efficient fluid handling in tasks that involve aggressive or sensitive media. Their real-world applications span multiple operational needs, including:

Accurate Chemical Dosing: Used to inject precise amounts of chemicals—such as acids, alkalis, or coagulants—into a process line for pH control, disinfection, or reaction balancing. Ideal for continuous or intermittent dosing scenarios.

Safe Fluid Transfer: Enables secure transfer of corrosive or hazardous liquids from one container to another, such as moving sulfuric acid from a storage tank to a reactor or mixing chamber.

Closed-Loop Circulation: Maintains continuous movement of chemical solutions within sealed systems, such as etching baths, cooling circuits, or scrubbing units, ensuring uniform chemical concentration and temperature.

The chemical pump is an essential tool for industries requiring safe and reliable handling of corrosive or specialized liquids. Its high chemical resistance, leak-proof design, and consistent performance make it ideal for a wide variety of fluid transfer applications. Whether for large-scale production or precision lab use, a chemical pump ensures safety, efficiency, and long-term value.