E01B 200-04 M1-1.4

Digital Dosing Pump Systems are advanced fluid handling solutions designed to provide precise and reliable chemical dosing across a wide range of industrial applications. Featuring intelligent control modules and customizable flow range settings, these pumps can adapt to various process requirements, from small-scale laboratory tasks to large-scale manufacturing operations. The product lineup includes compact high-accuracy units as well as more sophisticated models equipped with multifunctional digital interfaces, ensuring a suitable option for every application.

Engineered for smooth, pulse-free fluid delivery, these dosing pumps guarantee consistent and accurate dosing even in fluctuating system conditions. Their stable output minimizes variations caused by pressure changes or feed inconsistencies, which is critical for maintaining process quality and efficiency. The pumps offer versatile programming capabilities, allowing users to select from multiple operating modes such as flow-proportional dosing, batch dosing, and manual or automated control.

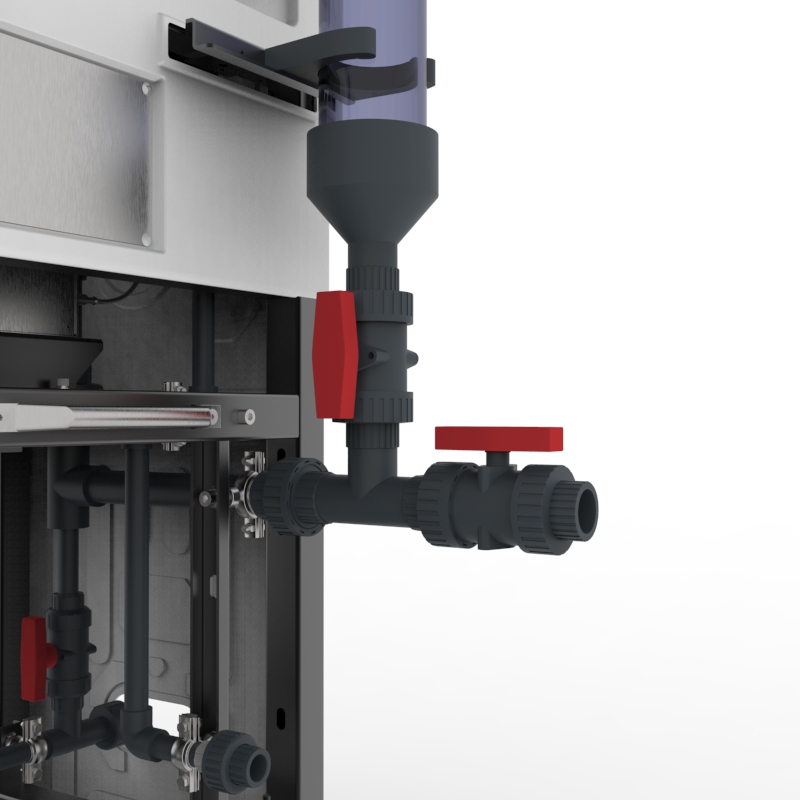

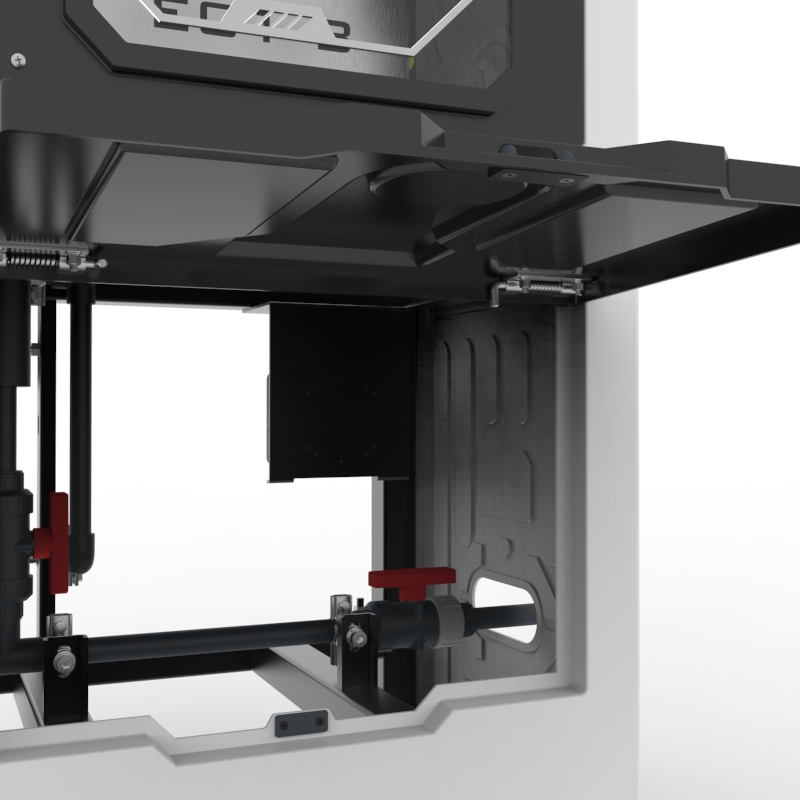

The dosing pump system is a cutting-edge solution designed to deliver accurate, consistent, and automated chemical dosing across a variety of demanding industrial processes. Engineered for quick installation and easy operation, this system combines advanced control features with durable construction to handle even the most challenging fluids—including viscous, corrosive, or sensitive media—while maintaining precise measurement and flow stability.

Key Features and Advantages

Quick Installation & Easy Operation

The modular design and intuitive user interface enable rapid setup and straightforward control, minimizing downtime and reducing the need for specialized training. This user-friendly approach ensures that the dosing pump system can be deployed efficiently, whether in new installations or as retrofits.

Precise Measurement & Consistent Dosing

With advanced digital control and high-accuracy metering technology, the compact designed dosing pump system provides stable, pulse-free fluid delivery regardless of pressure fluctuations or feed variability. This precision helps maintain product quality, reduce chemical waste, and ensure safe handling of critical additives.

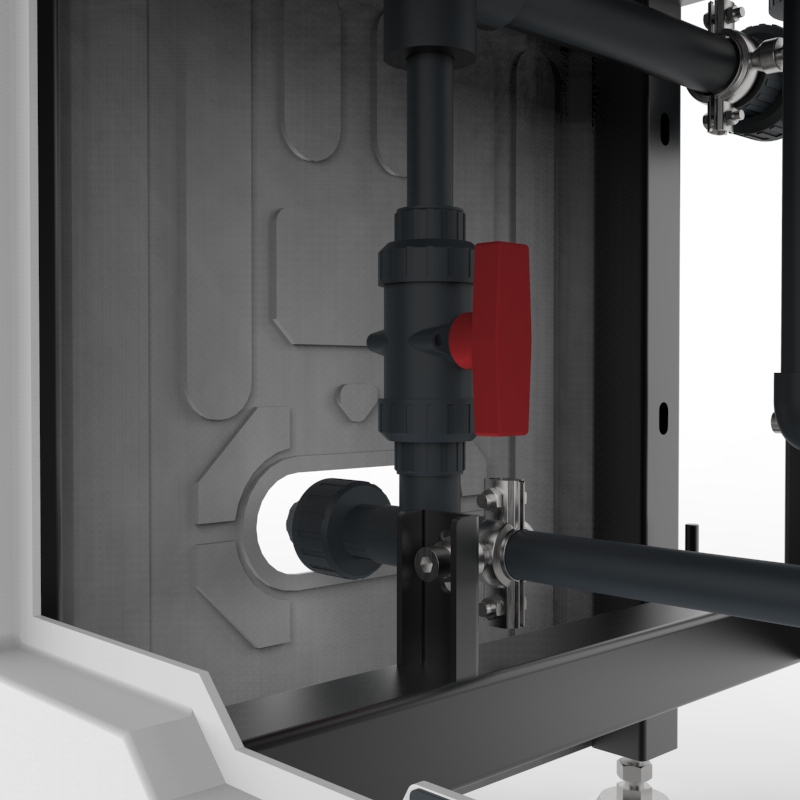

Condition Monitoring & Anomaly Detection

Integrated sensors constantly monitor flow rates, pressure, and operational status, providing real-time data and alerts. The system detects anomalies such as flow interruptions or pressure deviations early, allowing for preventive maintenance and avoiding costly downtime.

Multiple External Control Options

Compatible with a wide range of control signals—including analog, digital, and fieldbus protocols—the system can integrate seamlessly with plant-wide automation solutions like SCADA and PLC systems. This connectivity allows for remote control, data logging, and synchronized operation within complex process environments.

Automatic Flow Control & Adaptive Dosing

The pump automatically adjusts dosing rates based on real-time feedback, maintaining target flow even under varying process conditions. This feature is especially valuable in applications requiring precise chemical addition and responsiveness to sensor data, improving process efficiency and safety.

Robust Design for Harsh Fluids

Constructed with temperature-resistant materials and smooth internal surfaces, the dosing pump system protects delicate enzymes, bio-catalysts, and corrosive chemicals during transfer. Its design minimizes shear and turbulence, preserving the structural integrity of sensitive fluids while ensuring reliable, long-term performance.

Ideal Applications

1. Chemical and Smelting Acid Additives

In metallurgy and chemical processing, accurate dosing of acids such as sulfuric and hydrochloric acid is vital for refining and smelting operations. The dosing pump system handles corrosive media with high precision and safety, ensuring consistent additive delivery to optimize chemical reactions and improve product quality.

2. Industrial Cooling System Scale Inhibitor Addition

Large industrial cooling systems require continuous dosing of scale inhibitors and corrosion preventives to maintain system efficiency and protect equipment. The pump’s pulse-free flow and automatic control guarantee stable additive injection, helping prevent costly maintenance and downtime caused by scaling and corrosion.

3. Metallic and Non-Metallic Beneficiation Chemicals Dosing

In mining and mineral processing, precise dosing of flotation agents, dispersants, and pH regulators is critical for efficient ore beneficiation. The dosing pump system’s robust construction and adaptive flow control allow it to handle abrasive slurries and maintain consistent chemical feed, improving recovery rates and reducing operational costs.

Supporting Sustainable and Efficient Processes

The dosing pump system’s programmable interface supports various operating modes, including batch, pulse, and continuous dosing, making it ideal for diverse applications such as bioreactors and enzymatic pre-treatment tanks in bioenergy facilities. Optional real-time flow monitoring enables adaptive dosing based on sensor feedback, enhancing conversion efficiency and reducing resource consumption.

Designed for precision, durability, and operational flexibility, the dosing pump system is an indispensable tool in modern industrial chemical dosing. Its combination of quick installation, easy operation, precise measurement, and intelligent control ensures optimal performance across harsh and variable environments.