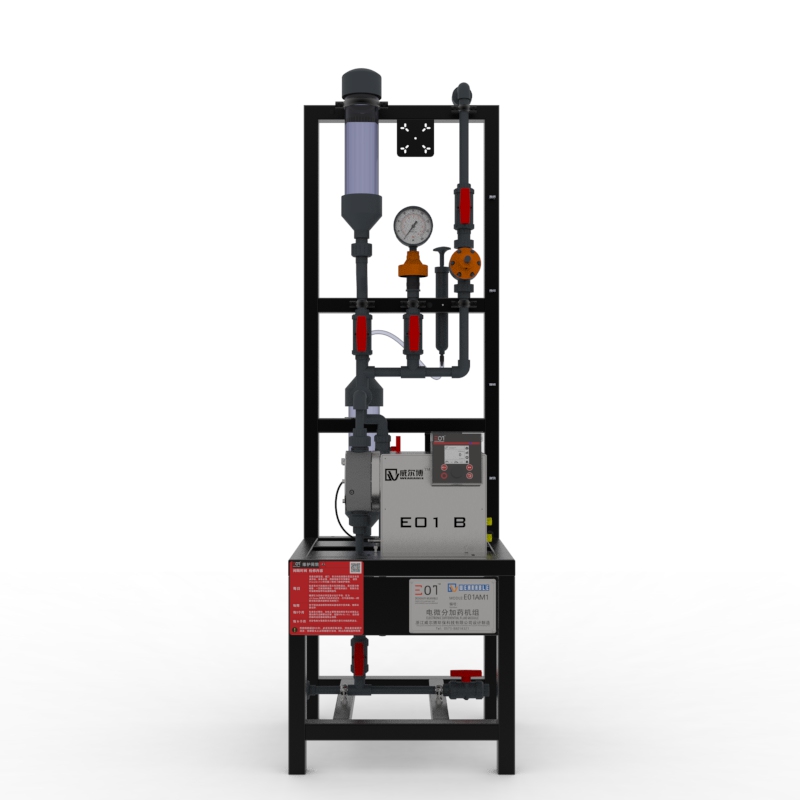

E01B 200-04 M1

Digital dosing pump systems deliver precise and stable chemical dosing through smart control and flexible flow configurations. Suitable for both single-point dosing and complex multi-stage systems, they ensure accurate, pulse-free fluid delivery across industries such as water treatment, energy materials, metallurgy, and laboratory applications. Programmable functions support batch dosing, flow-proportional control, and integration with external automation systems. Each unit can operate independently or within a network. Digital interfaces and condition monitoring provide real-time visibility and control, improving reliability while reducing manual operation and maintenance requirements.

The dosing pump system is an advanced solution engineered for precise, reliable, and automated chemical dosing across a range of demanding industrial environments. Designed for flexibility and control, it integrates seamlessly into both standalone operations and fully automated process lines. With features such as quick installation, easy operation, and precise measurement, this system ensures optimal dosing performance while reducing operational complexity and maintenance requirements.

At its core, the dosing pump system delivers highly accurate and pulse-free dosing performance. Whether the application involves corrosive chemicals, sensitive enzymes, or high-viscosity additives, the system ensures consistent flow with minimal deviation, making it indispensable for operations where precision is critical

Key Features and Advantages

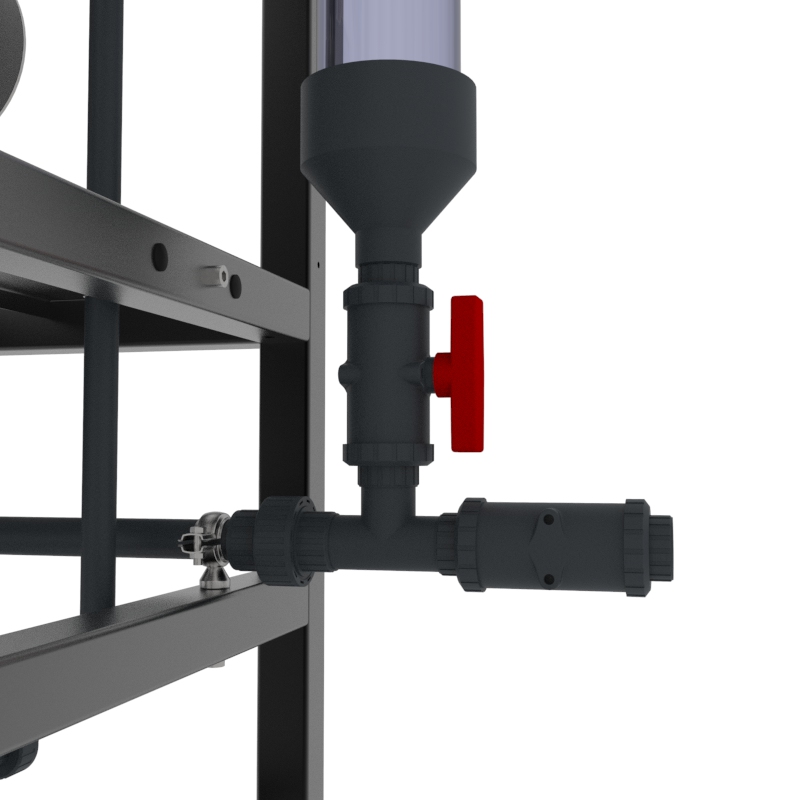

1. Quick Installation & Easy Operation

The laboratory scale dosing pump system is built with modularity in mind, enabling fast setup and intuitive control. Even operators with minimal technical training can deploy and manage the system effectively, reducing labor costs and minimizing setup time. The plug-and-play configuration makes it ideal for retrofitting or upgrading existing dosing systems.

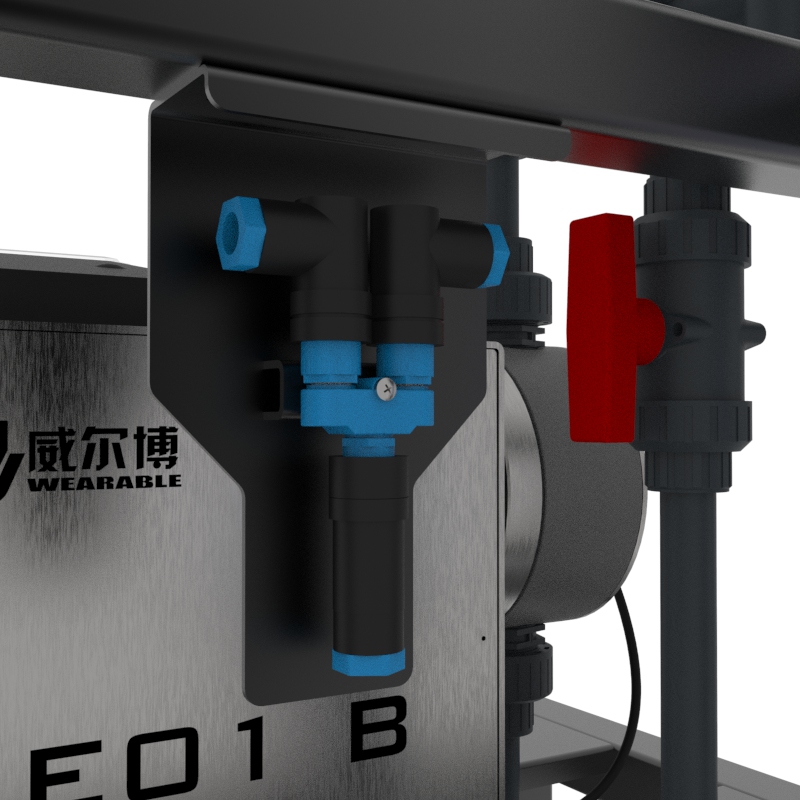

2. Precise Measurement & Pulse-Free Delivery

Accurate dosing is essential for maintaining process quality and minimizing chemical waste. The dosing pump system achieves high-precision fluid delivery through digital calibration and flow control, even in low-volume or variable-pressure conditions. This ensures consistent results, product uniformity, and operational efficiency.

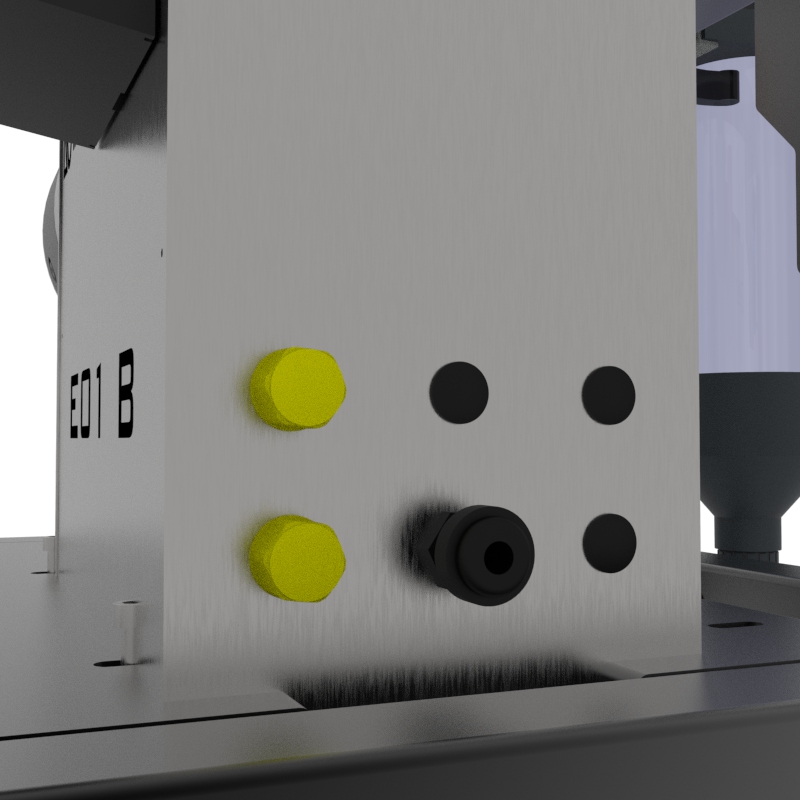

3. Condition Monitoring

The built-in monitoring system constantly assesses flow rate, pressure levels, and system performance. Real-time alerts notify operators of anomalies such as clogs, leaks, or flow interruptions, allowing for rapid corrective action. This predictive maintenance capability reduces unplanned downtime and extends the lifespan of critical equipment.

4. Various Operating Modes

From flow-proportional dosing to batch control and manual operation, the pump system supports multiple dosing strategies. This makes it adaptable to a variety of dosing scenarios—whether it's continuous additive injection in energy manufacturing or timed nutrient dosing in bio-reactors.

5. Automatic Flow Control & Anomaly Detection

To safeguard both the dosing process and surrounding equipment, the system offers automatic flow regulation and anomaly detection. If pressure or flow deviates beyond set thresholds, the system will trigger alarms, adjust output automatically, or even shut down to prevent damage—ensuring safe and accurate dosing at all times.

Application Scenarios

1. New Energy: Copper Foil Manufacturing Additive Dosing

In lithium battery production, the copper foil coating process requires extremely precise chemical dosing to control film thickness and electrical properties. The dosing pump system ensures consistent additive delivery—such as leveling agents and brighteners—into the production line. Its ability to maintain stable flow and adjust to variable operating conditions enhances product quality and manufacturing efficiency.

2. Water & Wastewater Treatment: Chemical Dosing

Municipal and industrial water treatment facilities rely on accurate dosing of chlorine, flocculants, and pH regulators. The dosing system’s pulse-free delivery and real-time flow monitoring are especially critical here, helping maintain water quality and meet environmental compliance standards.

3. Bioenergy: Enzyme Additive Injection

In biogas and bioethanol production, enzyme dosing must be precisely timed and proportioned to optimize microbial activity and maximize gas or alcohol yield. The dosing pump system’s flexible programming and automatic adjustment features make it ideal for handling delicate bio-additives that are sensitive to shear or inconsistent flow.

The dosing pump system is a powerful, intelligent, and dependable tool for modern chemical dosing tasks. With its emphasis on precision, flexibility, and real-time control, it empowers operators to optimize processes, reduce waste, and ensure long-term operational reliability. Whether in new energy manufacturing, water treatment, or bioenergy production, this system delivers the accuracy, safety, and performance today's industries demand.