-

E01A 060-04More

E01A 060-04More -

E01A 042-07More

E01A 042-07More -

E01A 090-03More

E01A 090-03More -

E01B 200-04More

E01B 200-04More -

E01C 450-03More

E01C 450-03More -

E01A 7.5-14More

E01A 7.5-14More -

E01B 120-05More

E01B 120-05More -

E01A 30-08More

E01A 30-08More -

E01C 450-03-2More

E01C 450-03-2More -

E01C 900-03More

E01C 900-03More -

E01C M1-B.557More

E01C M1-B.557More -

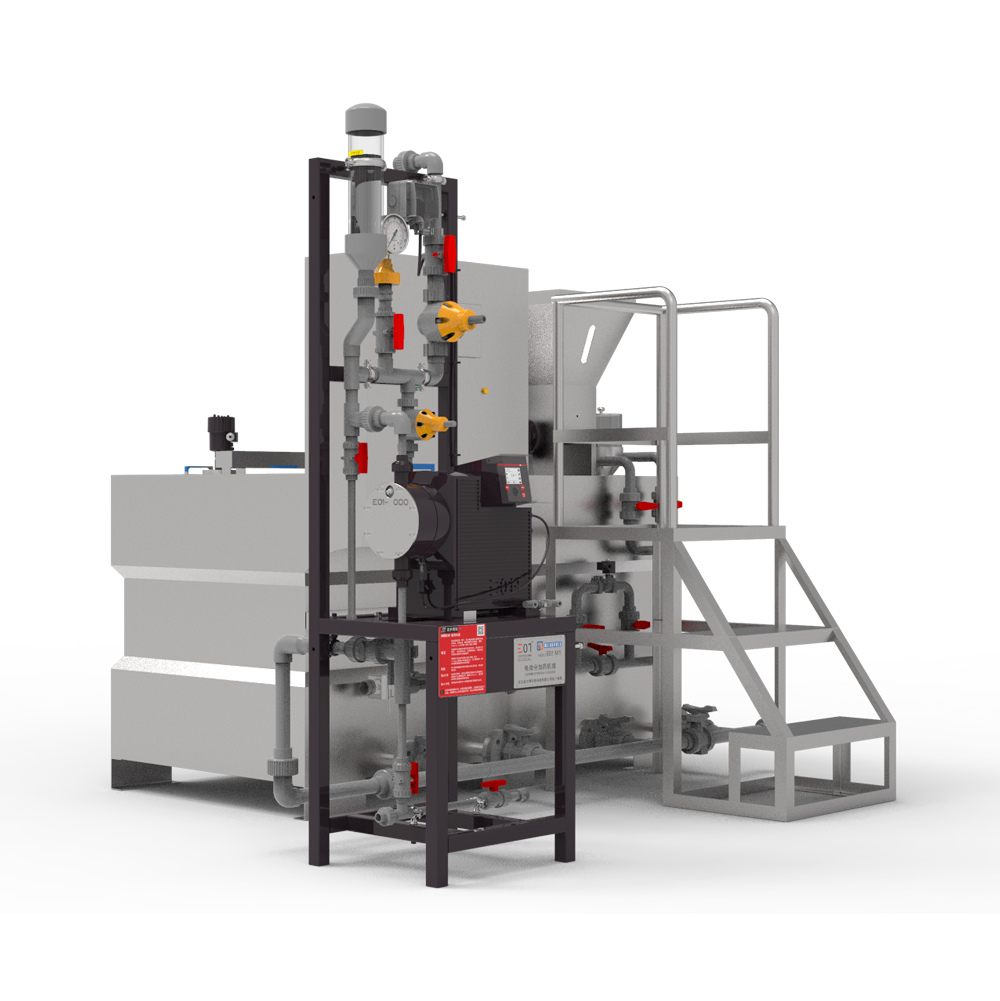

PAM+E01+M1More

PAM+E01+M1More

What Are Precise Digital Dosing Pumps Used For?

Digital Dosing Pumps are essential tools for precise and reliable fluid handling in industries that require accurate chemical dosing. Unlike conventional pumps, digital dosing systems are equipped with advanced control features, intelligent monitoring, and high-resolution adjustment capabilities, making them suitable for both low- and high-viscosity fluids across a wide range of applications.

One of the core functions of digital dosing pumps is quantitative fluid delivery. Whether it’s controlling the pH in a wastewater treatment plant, injecting acids in metal processing, or delivering enzyme additives in bioenergy systems, the ability to deliver exact amounts of liquid is crucial. These pumps support continuous, batch, or timed dosing, and can be finely tuned to respond to variations in flow rate, pressure, or chemical concentration.

In high-precision environments—such as laboratories, printing and dyeing processes, and pharmaceutical dosing—digital pumps ensure that even the smallest amounts are delivered with accuracy. Advanced motor algorithms, like vector control and high-speed pulse modulation, allow for dosing errors as low as ±0.2%.

Digital dosing pumps are also employed for anti-clogging and flushing operations, ensuring system cleanliness and uninterrupted operation. The inclusion of self-diagnostics and anomaly detection further supports preventive maintenance, reducing the likelihood of downtime and extending the life of critical components.

Key Usage Locations Include:

Water and Wastewater Treatment Facilities

Digital dosing pumps manage the addition of coagulants, flocculants, chlorine, and pH stabilizers. Their precision is critical for meeting regulatory standards and ensuring the safe treatment of municipal and industrial wastewater.

Automobile Manufacturing Plants

In automotive production, dosing pumps are used to deliver paint additives, color masterbatches, and other process chemicals. Precision here ensures consistent product quality and finish.

New Energy and Copper Foil Manufacturing

In the production of lithium-ion batteries and copper foil components, digital dosing pumps are used to apply surface treatment agents and etching additives. These tasks require pumps that can maintain stability despite high fluid viscosity and abrasive materials.

Metallurgical and Chemical Processing Sites

These pumps manage acid, alkali, and other reactive solutions, delivering them at precise rates to ensure reaction control and material consistency in metal extraction or processing systems.

Industrial Cooling Systems

By adding scale inhibitors and anti-corrosion agents to water systems, digital pumps protect infrastructure and maintain operational efficiency.

Bioenergy and Artificial Culture Facilities

In bioenergy production, enzyme additives and microbial nutrients must be delivered with precision. Digital dosing pumps help maintain consistent process conditions for optimal yield.

Laboratories and R\&D Settings

Whether in pharmaceutical labs or materials testing environments, digital pumps ensure reproducibility and accuracy for high-sensitivity chemical experiments.

This diversity of applications shows how digital dosing pumps serve not only as a functional part of industrial systems but also as a control point for optimizing safety, efficiency, and compliance.

Frequently Asked Questions

Q1: What is the accuracy of your digital metering pumps?

A1: Our pumps have an accuracy of ±0.24%, certified by national professional institutions.and we possess the corresponding certification documents.

Q2: What materials are used in the pump construction?

A2: We use high-quality materials such as PTFE, PVC, and stainless steel, ensuring durability and chemical resistance.

Q3: Can your pumps handle corrosive chemicals?

A3: Yes, our pumps are designed to handle a wide range of corrosive and abrasive chemicals. Corrosion-resistance