What Is a Chemical Pump?

A chemical pump is a specialized fluid-transfer device engineered to move chemical substances safely and efficiently while preventing leakage, contamination, and degradation of internal components. Unlike general-purpose pumps, chemical pumps must accommodate a wide spectrum of fluid characteristics, including acidity, alkalinity, viscosity, toxicity, and temperature sensitivity.

To achieve stable and safe performance, chemical pumps commonly feature:

Corrosion-resistant materials such as PTFE, PVDF, PP, stainless steel, or alloy steel

Leak-free sealing mechanisms, including diaphragm designs, magnetic couplings, or robust mechanical seals

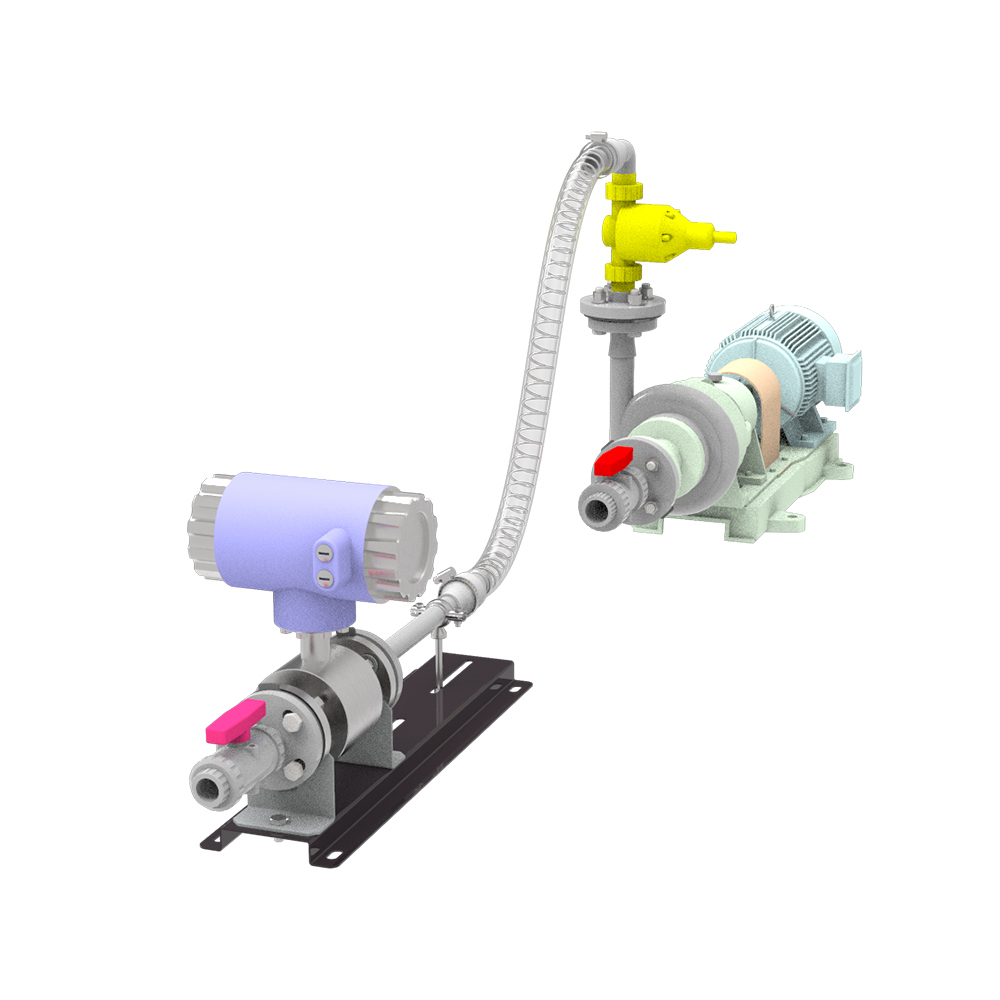

Precise flow and pressure control, especially important for dosing, metering, and proportional injection

Compatibility with automation, allowing integration with PLC or SCADA systems

Self-priming or high-suction capabilities for challenging chemical feed conditions

Depending on application requirements, chemical pumps allow continuous transfer, batch metering, recirculation, pH control, disinfection, inhibitor dosing, or high-purity delivery in closed-loop processes.

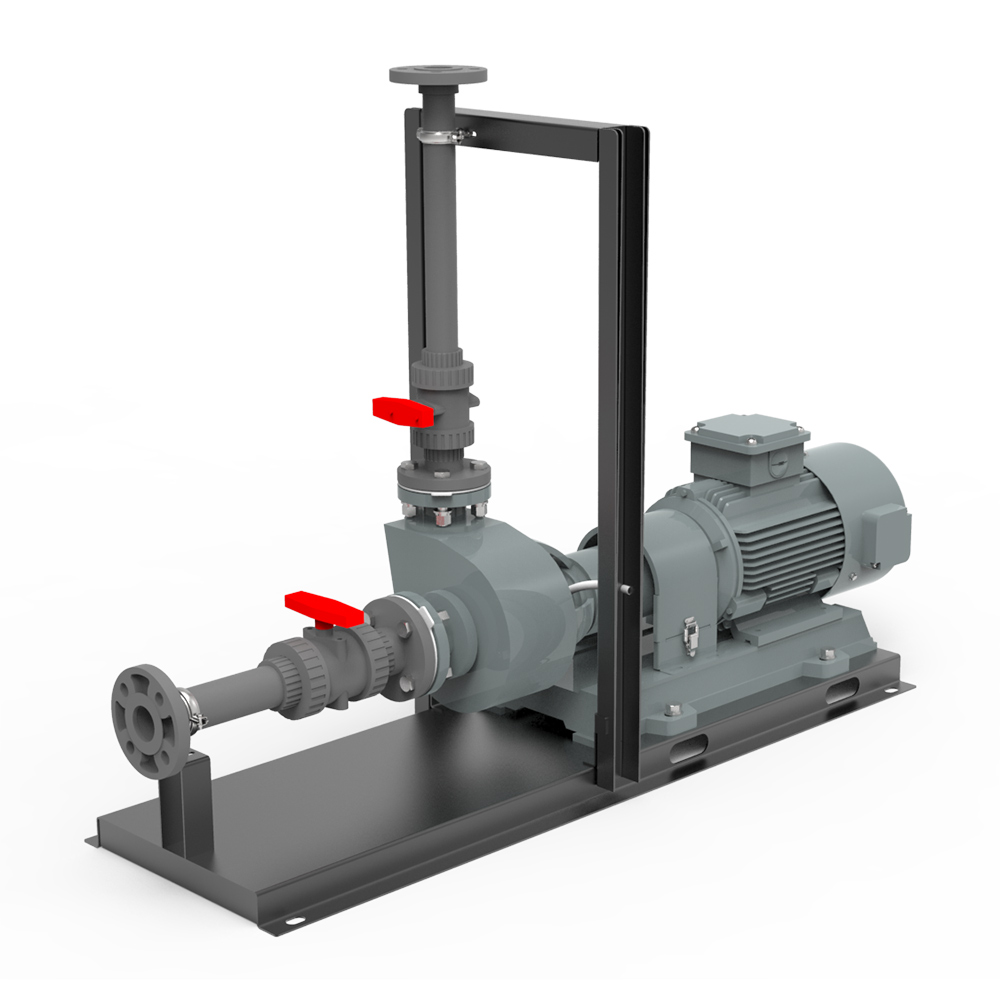

Common pump types used for chemical handling include:

- Mechanical and hydraulic diaphragm pumps

- Magnetic-drive centrifugal pumps

- Gear and screw pumps for viscous chemical media

- Digital dosing pumps for high-precision injection

Each design offers unique strengths depending on operating pressure, chemical compatibility, dosing accuracy, and system layout.

Advantages of Using Chemical Pumps

1.Safe Handling of Corrosive and Hazardous Chemicals

Chemical pumps are specifically engineered to prevent operator exposure and environmental leakage. With corrosion-resistant wetted parts and sealed hydraulic chambers, they maintain containment when handling acids, alkalis, oxidizers, disinfectants, or solvents.

2.High Accuracy and Consistency

For processes requiring precise chemical ratios—such as water treatment, metal finishing, or pharmaceutical formulation—chemical pumps deliver stable flow with minimal pulsation. Advanced designs, especially digital dosing pumps, achieve accuracy levels suitable for critical chemical injection.

3. Long Service Life and Reduced Maintenance

By incorporating durable diaphragms, chemically inert materials, and reliable valve mechanisms, chemical pumps minimize wear even under continuous operation. Their ability to maintain stable performance reduces the frequency of part replacement and unplanned downtime.

FAQ

How often should a chemical pump be serviced?

Regular servicing is important for safe and efficient pump operation. The required interval varies based on pump type, chemical properties, and operating conditions. Routine inspections should follow the recommended schedule in the equipment documentation to prevent unexpected downtime.

What safety measures are necessary when working with a chemical pump?

Safe use requires appropriate PPE, proper ventilation, and verification that the pumped chemical is compatible with all wetted materials. Operators should also be familiar with emergency procedures in case of leaks or accidental exposure.

How should a user respond if a chemical pump shows signs of malfunction?

If the pump exhibits leaks, unusual noise, reduced flow, or unstable operation, it should be shut down immediately. Continuing to run a malfunctioning pump increases safety risks. Professional inspection or repair should be arranged before putting the pump back into service.